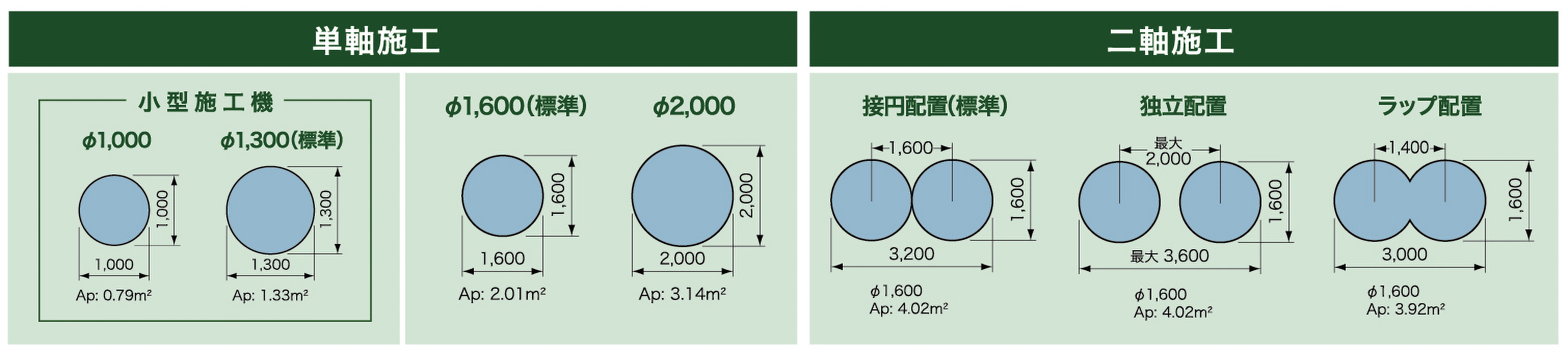

Deep Mixing Methods that Deliver Large-diameter, High Quality Improvement Columns

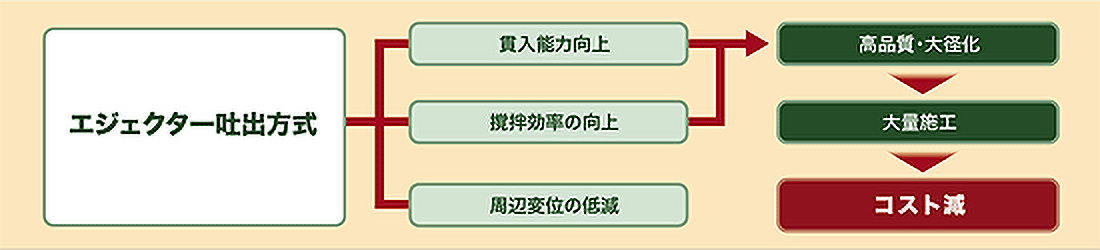

The CI-CMC and CI-CMC-HA methods are deep mixing methods that form large-diameter high quality improvement columns through the development of an “ejector discharge” device that uses compressed air to spray slurry as a mist.

Displacement in the surrounding ground is greatly reduced, allowing implementation close to existing structures in urban areas. Large-volume implementation maintaining high quality reduces costs.

The low displacement CI-CMC method (pile diameter 1,600mm x 2 pipes) was newly listed in the 2017 Ministry of Land, Infrastructure, Transport and Tourism publication of civil engineering quantity standards as a slurry mixing, twin-axis implementation (displacement minimizing type) method of 1,600mm pile diameter.

| New civil engineering technology | 2017年1月 (財)先端建設技術センター 建設技術審査証第2804号 |

|---|---|

| NETIS registered | QS-160049-A(HA) |

Features:

- High quality large-diameter columns

Improved mixing effectiveness delivers large-diameter highly uniform columns.

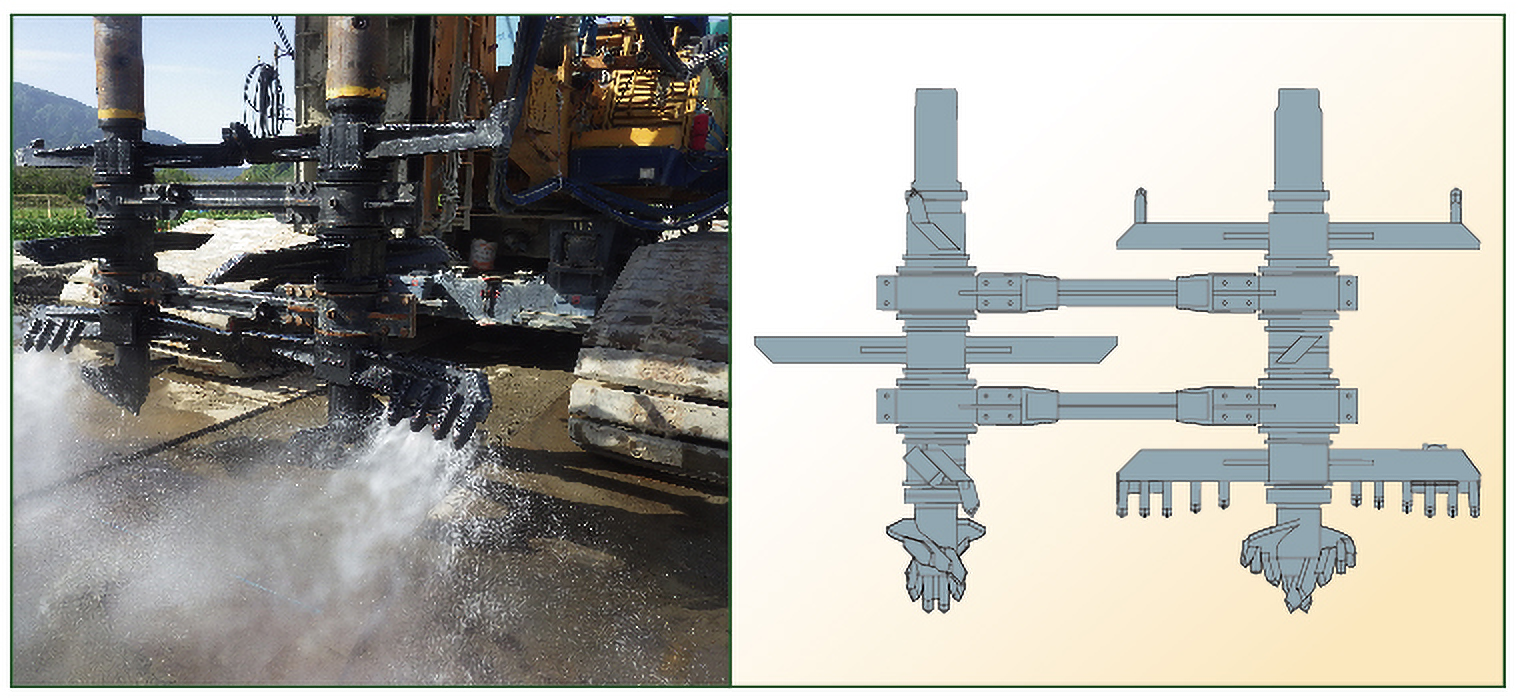

- Outstanding driving capability

Greater driving capability makes mixing possible in ground where penetration resistance is high.

- Low displacement method

The effect of using compressed air significantly reduces displacement in surrounding ground.

- HA: Implementation possible in hard ground

With more advanced mixing blades, implementation possible from hard ground (N value 50) to soft soil (N value 15).

- HA: Reduced costs and shortened schedules

No advance boring is needed in hard ground, reducing costs and shortening schedules.

- HA: Consistent strength in improved columns

Controlling the volume of compressed air used in ejector discharge limits strength variation in improvement columns.

- New Visios-3D® implementation management system

Visualizing implementation status, following record files and CIM (Concrete Information Modeling) allows mapping as 3D model.