Combining conventional mechanical mixing and high-pressure jet mixing.

This method combines the merits of conventional mechanical mixing with high-pressure jet mixing. It forms soil cement blocks leaving no unimproved part.

| New civil engineering technology | July 1999 Japan Institute of Country-ology and Engineering (JICE), 1st Technology Development Award |

|---|

Features

Cross jet injection

With the development of cross jet injection, because the jet mixing range is limited compared to regular high-pressure jet mixing methods…

- The diameter of the improvement columns can be carefully controlled without any effect from the ground

- Unconfined compression strength of the improvement columns can be freely selected within the standard range of 0.2-3.0MN/m

- The significantly improved mixing performance gives highly efficient implementation, and uniform columns can be formed.

Composite mixing

Compared to regular mechanical mixing methods, with composite mixing…

- Installation close to existing structures or between improvement columns can be achieved reliably and easily

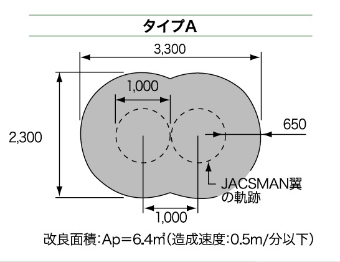

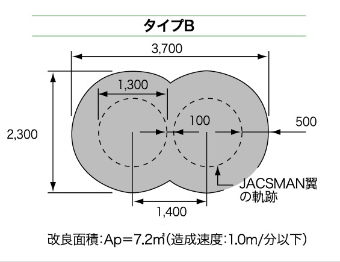

- Large section (more than 4 times the conventional) improvement columns can be formed.

- By stopping the cross jet injection the diameter of the improvement column can be changed at any depth as required.