| 論文題 |

著者名 |

学会・刊行物名 |

| 港湾施設における小型施工機を用いた液状化対策工法とその事例 | 竹内秀克,尾形 太 | 土木施工 2022年4月号 pp.76-79 |

| Study on SPT N-values and Relative Density | 矢部浩史,原田健二,伊藤竹史,渡辺英二 | 5th International Symposium on Cone Penetration Testing (CPT’22) pp.772-777 |

| 各種地盤における実地震・加振による サウンディング値の変化 | 原田健二 | 液状化に係わる被害のメカニズムと名称を考える委員会(地盤工学会関東支部) 2022-10-3 |

| 固化処理土で構築された岸壁の地震時挙動と安定性評価手法の検討 | 竹内秀克,高橋英紀(港湾空港技術研究所),府川裕史・浅田 英幸(東亜建設工業),NGUYEN Binh(五洋建設) | 土木学会論文集B3(海洋開発) 2022 年78巻2号 p. I_589-I_594 |

| Shaking table tests on level ground model simulating construction of sand compaction piles | 矢部浩史,古関純一(東大),原田健二, 田中肇一 | PBD-Ⅳ:Performance-based design in Earthquake Geotechnical Engineering pp 1231–1239 |

| Influence of Lateral Stress Ratio on N-value and Cyclic Strength of Sands Containing Fines | 原田健二,石原研而(中央大),矢部浩史 | International Conference on Performance-based Design in Earthquake Geotechnical Engineering pp.1524–1533 |

| 細粒分混り砂の異方応力状態における損失エネルギーと液状化強度の関係 | 坪井稜太・石川敬祐・安田 進(東電大),原田健二,出野智之 | 第57回地盤工学研究発表会 20-4-3-07 |

| 大型施工機による地盤改良の自動化施工 | 伊藤竹史,廣畑憲史,今給黎健一,加藤清揮 | 第57回地盤工学研究発表会 21-2-3-08 |

| 海底鉱物資源の揚鉱に用いるキャリア物質の粘性特性に及ぼす加圧履歴の影響(その1:B型粘度計) | 梅田洋彰,興井みのり・谷 和夫・野村 瞬(東京海洋大),鈴木亮彦,矢部浩史,冨田晃弘 | 第57回地盤工学研究発表会 21-10-4-05 |

| 海底鉱物資源の揚鉱に用いるキャリア物質の粘性特性に及ぼす加圧履歴の影響(その2:変水頭フロー試験) | 興井みのり(東京海洋大), 梅田洋彰,谷 和夫・野村瞬(東京海洋大),鈴木亮彦,矢部浩史,冨田晃弘 | 第57回地盤工学研究発表会 21-10-4-06 |

| Sphere pull-up tests to assess drag force on ore model and influence of the pipe wall on drag force in riser pipe | Choi Hongseok・谷 和夫・ 野村 瞬(東京海洋大),鈴木亮彦,矢部浩史,梅田洋彰 | 第57回地盤工学研究発表会 21-10-4-08 |

| 締固め砂杭打設過程を模擬した水平地盤模型の加振実験(砂杭材料の違いが改良効果へ及ぼす影響) | 冨田晃弘,原田健二, 矢部浩史,古関潤一 | 第57回地盤工学研究発表会 21-11-1-01 |

| SCP 工法における変位緩衝孔の効果と施工後強度調査 | 道平一史・稲川義洋(伏光組),高垣修太,田中隼矢 | 第57回地盤工学研究発表会 21-11-1-04 |

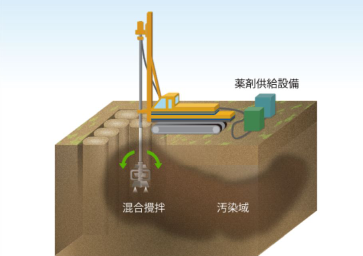

| 既設構造物直下の揺動式複流線固化材スラリー噴射撹拌工法(矩形タイプ)適用事例 | 林田敏彦,高田英典,日下仁志(中幸建設) | 第57回地盤工学研究発表会 22-8-1-03 |

| 静的締固め砂杭工法の施工に及ぼす回転の影響 | 矢部浩史,伊藤竹史,竹内秀克,髙田英典,吉田悠都 | 第57回地盤工学研究発表会 22-8-3-07 |

| 水中での空洞充填に適した材料の開発 | 高田英典,鈴木亮彦,伊藤竹史,矢部浩史,永石雅大,小林一男 | 第57回地盤工学研究発表会 22-11-3-07 |

| 地盤防災・環境保全に資する地盤改良技術の現状と展望 1.液状化対策 | 大島昭彦(大阪市大), 川崎哲人(竹中土木),新坂孝志(三信建設工業),中西康晴(エヌ、アイ、テイ),原田健二 | 材料 71巻, 8号 pp.719-726 |

| 石炭灰を使用したコンパクションパイル工法による取組み | 竹内秀克,尾形 太,中出雄也 | 基礎工2020年8月号 pp.60-62 |

| 静的締固め砂杭工法による既存杭撤去孔の新たな埋戻し技術 | 高田英典,竹内秀克,中村光男・沼本大輝・梶野実(長谷工),渡辺英次 | 基礎工2022年9月号 pp.52-54 |

| 静的締固め砂杭工法の改良範囲が杭の水平抵抗に与える影響 | 金子治(広工大),吉富宏紀 | 2022年度日本建築学会大会学術講演会 pp.357-358 |

| 細粒分を含む砂における静止土圧係数の増加がN値と液状化抵抗比に及ぼす影響 | 岡 有己,吉富宏紀,原田健二 | 2022年度日本建築学会大会学術講演会 pp.359-360 |

| 静的締固め砂杭工法による既存杭撤去孔の埋戻し施工実験 | 沼本大輝,中村光男,竹内秀克,高田英典 | 2022年度日本建築学会大会学術講演会 pp.519-520 |

| シルト質砂の異方応力状態における損失エネルギーと液状化強度の関係 | 坪井稜太・石川敬祐,安田 進(東電大),原田健二,出野智之 | 第77回土木学会全国学術講演会 III-290 |

| 静的締固め砂杭打設による実物大土層内での土圧計測 | 矢部浩史,竹内秀克,伊藤竹史,髙田英典,吉田悠都 | 第77回土木学会全国学術講演会 III-130 |

| 締固め砂杭工法を模擬した模型地盤における加振前後のコーン貫入試験 | 原田健二,冨田晃弘,矢部浩史,古関潤一(東大),佐藤剛司 | 第77回土木学会全国学術講演会 III-131 |

| Sphere pull-up and down tests to evaluate drag forces in viscous fluids to assess ore lifting capacity | 崔弘錫・谷 和夫・野村 瞬(東京海洋大), 鈴木亮彦,矢部浩史, 梅田洋彰 | "ICPMG 2022 10th International Conference on Physical Modelling in Geotechnics pp.468-473" |

| Falling head flow test to study pipe flow and rheological characteristics of carrier materials used for ore lifting from deep seafloor | 興井みのり・谷 和夫,野村 瞬(東京海洋大),鈴木亮彦,矢部浩史, 梅田洋彰 | "ICPMG 2022 10th International Conference on Physical Modelling in Geotechnics pp.538-541" |

| せん断波速度を利用した高圧噴射攪拌工法による改良体径評価方法の検討 | 山田 卓・大島昭彦(大阪公立大),伊藤竹史,原田健二 | 第15回地盤改良シンポジウム pp.165-172 |

| 河川堤体における仮設鋼矢板引抜跡への砂圧入式静的締固め工法の適用事例 | 中井寛(鉄建建設),永石雅大,高田英典,大久保直哉(鉄建建設),尾形 太 | 第15回地盤改良シンポジウム pp.225-230 |

| 静的締固め砂杭工法による既存杭撤去孔の埋戻し工法の開発 | 中村光男・沼本大輝(長谷工),高田英典,伊藤竹史,矢部浩史 | 第15回地盤改良シンポジウム pp.267-270 |

| SCP工法の改良効果のエネルギー的な視点からの考察 | 坪井稜太・石川敬祐,安田 進(東電大),原田健二, 出野智之 | 第15回地盤改良シンポジウム pp.499-506 |

| 締固め砂杭打設過程を模擬した水平地盤模型の振動台実験 -改良効果に及ぼす中詰め材料の影響- | 冨田晃弘,原田健二,矢部浩史,古関潤一(東大) | 第15回地盤改良シンポジウム pp.681-686 |

| SCP工法による締固め改良地盤の微視構造変化に関するX線CT模型実験 | 江副 哲,梅田洋彰,原田健二,佐藤宇紘,大谷 順 | "地盤工学ジャーナル Vol.17, No.4 pp.523-536" |

| 少子高齢化に向けたICT地盤改良への取り組み | 伊藤竹史,中出雄也 | 北海道土木技術会 土質基礎研究委員会 第21回技術報告会 pp.22-27 |

| "小型施工機による地盤改良自動打設システム GeoPilotⓇ-AutoPile の適用範囲の拡大" | 吉浦彰洋 | 建設機械施工 Vol.75 No.2 pp.64-67 |

| SCP工法に用いる竹チップ・RC混合材料の締固め・力学特性 | 山本航司・佐藤研一,古賀千佳嗣(福岡大),渡辺英次,布川直矢 | 令和4年度 土木学会西部支部研究発表会 pp.369-370 |

| 改良効果の不均一性を考慮したSCP改良地盤の地震時応答解析 | 澤田尚樹・笠間清伸,古川全太郎(九大),原田健二,竹内秀克,日髙 亮 | 令和4年度 土木学会西部支部研究発表会 pp.379-380 |

| 水理機能とライフサイクルコストを考慮した消波工の最適な補修断面の推定 | 西尾彰文・荒木進歩(大阪大),澁谷容子・神田泰成(東洋建設),久保田真一 | "土木学会論文集B2 (海岸工学) Vol.78,No.2 pp.679-684" |

| 消波ブロックのリアルタイム据付シミュレーション手法の開発 | 三井 順,久保田真一,橋田雅也,昇 悟志 | "土木学会論文集B2 (海岸工学) Vol.78,No.2 pp.685-690" |

| 越波実験における消波ブロックのラフネスファクターへの影響要因に関する検討 | 澤田龍輝・荒木進歩(大阪大),渡部未樹久,三井 順,久保田真一 | "土木学会論文集B2 (海岸工学) Vol.78,No.2 pp.697-702" |

| 袋型根固め材による洋上風力発電設備の洗掘防止効果と模型の縮尺効果に関する大規模水理模型実験 | 小林 航(前田工繊),関谷勇太・鈴木英樹(ナカダ産業),青田 徹,松田節男,高橋武志(港湾空港技術研究所),下迫健一郎 (沿岸技術研究センター),鈴木高二朗(港湾空港技術研究所) | "土木学会論文集B2 (海岸工学) Vol.78,No.2 pp.709-714" |

| 消波工の断面形状の変化および堤体天端高が波力低減効果に与える影響 | 澁谷容子・神田泰成(東洋建設),西尾彰文・荒木進歩(大阪大),久保田真一,小竹康夫(東洋建設) | "土木学会論文集B3 (海洋開発) Vol.78,No.2 pp.445-450" |

| 石垣島崎枝湾におけるサンゴ礁の食物網の推定 | 柴田早苗,伊藤 靖・當舎親典(漁港漁場漁村総合研究所),完山 暢(水産土木建設技術センター),末永慶寛(香川大) | "土木学会論文集B3 (海洋開発) Vol.78,No.2 pp.679-684" |

| 袋型根固め材による洋上風力発電設備の洗掘防止効果と敷設構造に関する水理模型実験 | 関谷勇太・鈴木英樹(ナカダ産業),青田 徹,久保田真一,土橋和敬・小林 航(前田工繊),鈴木高二朗(港湾空港技術研究所),下迫健一郎 (沿岸技術研究センター) | "土木学会論文集B3 (海洋開発) Vol.78,No.2 pp.907-912" |

| 袋型根固め材に繁茂した植生が河川護岸に及ぼす影響 | 萩原照通,会田俊介・風間 聡(東北大) | "土木学会論文集G (環境) Vol.78,No.5 pp.135-142" |

| 消波工嵩上げ時における消波ブロックのかみ合わせに関する定量的評価の試み | 久保田真一,三井 順,松本 朗 | "土木学会年次学術講演会 (第77回) Ⅱ-75" |

| 長周期波対策マウンド構造物の反射率推定式の改良検討 | 三井 順,長谷川巌(エコー),田中真史,久保田真一,松本 朗 | "土木学会年次学術講演会 (第77回) Ⅱ-82" |

| 消波工不連続部の越波対策に関する平面水理実験による検討 | 古城鉄也・瀬口 均・江川祐輔(関西エアポート),酒井大樹(東洋建設),木下勝尊 | "土木学会年次学術講演会 (第77回) Ⅱ-172" |

| 防波堤背面に設置した遊水部付き長周期波対策工の越波に対する安定性 | 山上健太郎,渡部未樹久,三井 順,久保田真一,松本 朗 | "土木学会年次学術講演会 (第77回) Ⅱ-173" |

| 消波ブロックの空隙率と形状がラフネスファクターに及ぼす影響 | 澤田龍輝・荒木進歩(大阪大),久保田真一,三井 順,渡部未樹久 | "2022年度土木学会関西支部年次学術講演会 ポスターⅡ-14" |

| 消波ブロックのリアルタイム据付シミュレーション | 三井 順,久保田真一,橋田雅也,昇 悟志 | "北陸地方建設事業推進協議会 令和4年度建設技術報告会報文集 pp.25-28" |

| Maintenance technology of wave-dissipating works using 3D data | 橋田雅也,昇 悟志 | PIANC Yearbook 2022 |

| An experimental study on oscillatory characteristics of young mangroves behind a portable reef | S. Sreeranga・高木泰士(東工大),久保田真一,三井 順 | Coastal Engineering Journal |

| Numerical analysis about suspended sediment deposition around filter unit | 萩原照通,会田俊介(東北大),渡邉一也(秋田大),風間 聡(東北大) | "39th IAHR World Congress pp.2590-2598" |

| SPH modelling of the interaction between a solitary wave and moving Tetrapods of a breakwater | 三井 順,C. ALTOMARE(カタルーニャ工科大),A.J.C. CRESPO・J.M. DOMÍNGUEZ(ヴィーゴ大),久保田真一,M. GÓMEZ-GESTEIRA(ヴィーゴ大),鈴木智弘(フランダース水理研究所) | "39th IAHR World Congress pp.4478-4487" |

| サンドコンパクション工法の杭芯材への石炭灰等の有効活用による環境負荷低減 | 広重敬嗣(大成建設),藤井嵩大(JERA),西野日出樹・川崎雄大(大成建設),尾形太 | 地盤工学会誌2021年4月号 Journal of JGS Vol.69 Nno.4 Ser.No.759 pp17-20 |

| 第31不動号(サンドコンパクション船) | 古庄哲士 | 作業船 台343号 pp.24-27 |

| SCP(サンドコンパクションパイル)工法による改良効果に関する研究の変遷と知見 | 原田健二 | 基礎工 2021年5月号 (第49巻 第5号 通巻574号) pp.48-51 |

| CI-CMC-HA工法 (QS-160049-VE) と CI-CMC-HG工法 (QS-200009-A) ~硬質地盤に適応した大径・低変位の深層混合処理工法~ | 梅田洋彰 | 月刊「建設機械」2021年6月号 pp.1-5 |

| Centrifuge study on the effect of the SCP improvement geometry on the mitigation of liquefaction-induced embankment settlement(SCP工法による幾何学的改良範囲の液状化に起因する盛土沈下対策に関する遠心模型実験) | 李楊・北詰昌樹・高橋章浩(東工大),原田健二,大林淳 | Soil Dynamics and Earthquake Engineering Volume 148, September 2021, 106852 |

| 海底鉱物資源の揚鉱に用いるキャリア物質のレオロジー特性の計測(その1) | 古庄哲士,折田清隆・谷和夫(東京海洋大),鈴木亮彦 | 第56回地盤工学研究発表会 12-1-2-01 |

| コーン貫入試験による打設直後の高圧噴射撹拌工法の改良体の強度調査 | 武田尚也,原田健二,伊藤竹史 | 第56回地盤工学研究発表会 12-1-3-06 |

| 河川堤防における砂圧入式静的締固め工法の変位対策事例 | 梅田洋彰,森哲夫(新井組),古庄哲士,木下洋樹,永石雅大,中井啓二 | 第56回地盤工学研究発表会 12-1-4-03 |

| 細粒分混り砂の異方応力状態による液状化強度特性と損失エネルギー | 町田亘・石川敬祐(東電大),原田健二,安田進(東電大),出野智之 | 第56回地盤工学研究発表会 12-4-4-03 |

| SCP打設角度が異なる液状化地盤の挙動に関するFEM解析 | 藤本翔太・北詰正樹・高橋章浩(東工大),大林淳,原田健二 | 第56回地盤工学研究発表会 12-9-4-04 |

| 三隅発電所2 号機建設工事におけるライトサンド(クリンカアッシュ)を用いたSCP 工法の適用について | 高橋達郎(三井住友建設),田中隼矢,木下洋樹,安達光徳・秋山裕樹(中国電力) | 第56回地盤工学研究発表会 12-9-4-05 |

| 締固め砂杭打設過程を考慮した水平地盤模型の加振実験(その1) | 矢部浩史,原田健二,梅田洋彰,古関潤一・木村裕斗(東大) | 第56回地盤工学研究発表会 12-9-5-01 |

| 締固め砂杭打設過程を考慮した水平地盤模型の加振実験(その2) | 木村祐斗,古関潤一(東大),原田健二,矢部浩史,梅田洋彰 | 第56回地盤工学研究発表会 12-9-5-02 |

| 砂圧入式静的締固め工法による河川堤防基礎耐震化の事例 | 竹内秀克,尾形太,梅田洋彰 | 土木施工 令和3年8月号 pp.85-88 |

| 時代のニーズに応じて進化するSCP工法 | 原田健二 | 土木学会誌 Vol.106 No.9 September 2021 pp.40-42 |

| 締固め砂杭工法を模擬した模型地盤における加振前後のサウンディング試験 | 矢部浩史,古関潤一(東大),中澤博志(静岡理工科大) | 土木学会年次学術講演会 (第76回) III-84 |

| コーン貫入試験及び画像判断を用いた高圧噴射撹拌工法の出来形調査 | 武田尚也,原田健二,山下祐司,伊藤竹史 | 土木学会年次学術講演会 (第76回) III-93 |

| 簡易な液状化判定による東日本大震災でのSCP工法の改良効果の検証 | 石川敬祐・安田進(東電大),原田健二,出野智之,町田亘(東電大) | 土木学会年次学術講演会 (第76回) III-215 |

| 排土式変位低減型深層混合処理工法 2軸大径実証実験の報告(その4) 現場発現強度の結果及び考察 | 寺本崇宏(清水建設),山下勝司,河合拓也(テノックス),大古利勝己(あおみ建設) | 土木学会年次学術講演会 (第76回) VI-118 |

| ニューマチックケーソン支持力対策としての静的締固め砂杭工法の適用事例(その1)~軟弱地盤の施工に伴う変位対策~ | 川村理史・後藤修二(大成・岩田地崎・関電工JV),大塚文昭・吉田哲也(東京水道局),竹内秀克,菅章悟 | 土木学会年次学術講演会 (第76回) VI-119 |

| ニューマチックケーソン支持力対策としての静的締固め砂杭工法の適用事例(その2)~地盤改良用鉄鋼スラグ混入地盤掘削土のハンドリング性の検証~ | 川村理史・後藤修二(大成・岩田地崎・関電工JV),大塚文昭・吉田哲也(東京水道局),竹内秀克,菅章悟 | 土木学会年次学術講演会 (第76回) VI-120 |

| 大型地盤改良機で初めてとなる自動打設システム「GeoPilot®-AutoPile」 | 鈴木亮彦,伊藤竹史,竹内秀克,中谷真弥 | セメント・コンクリート No.898, Dec. 2021 pp.26-30 |

| 最新の地盤改良技術と動向 | 中出雄也,尾形太 | 地盤工学会北海道支部 技術報告集第62号 pp.330-335 |

| 細粒分を含む砂の貫入抵抗値と液状化強度に及ぼす水平応力比の影響 | 原田健二,石原研而(中央大),矢部浩史 | 材料 2022年 71巻 1号 p. 73-78 |

| 締固めによる液状化対策工法の変遷とその事例 | 村上太基,梅田洋彰,竹内秀克 | 月刊「建設機械」2022年3月号 pp.30-35 |

| 複流線固化材スラリー噴射撹拌工法の概要と施工例 -FTJ工法・FTJ-FAN工法- | 竹内秀克,田口雄一 | 基礎工 2022年3月号 (第50巻 第3号 通巻584号) pp.66-68 |

| 点群データを活用した構造物の施工管理に対する試行 | 小林 純,植村飛鳥 | 土木学会年次学術講演会 (第76回) Ⅵ-712 |

| Ⅱ期線工事での超硬質な硬岩掘削の工夫 | 佐藤直輝・袴田武大(東日本高速道路),後藤重信,平久保良二,塩川元章 | 土木施工 2021年10月号 pp.60-65 |

| 鳥の海PAランプ切替を含む軟弱地盤区間での土工事 | 清水尚志・成岡尚哉・阿南洵哉(東日本高速道路),堀井信雄,塩川元章,最上明好(アイサワ工業) | 土木施工 2021年10月号 pp.153-158 |

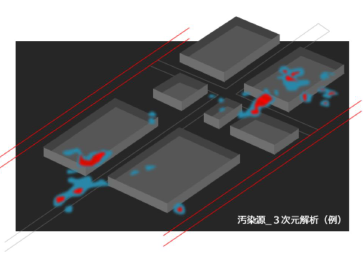

| 地盤改良技術を用いた土壌・地下水汚染の浄化対策技術 | 萩野芳章・髙田将文・長谷川拓也 | 土質基礎に関する「持続可能な社会に向けた地盤環境に関わる我社の貢献」技術報告会 |

| 海上地盤改良による自然由来重金属を含む盛上り土の環境対策について | 萩野芳章 | 土木施工2022年4月号pp.100-103 |

| Enhanced reactivity of dicalcium phosphate dihydrate with fluoride ions by coating with apatite nanoparticles | N. Okajima・ M. Tafu・ T. Toshima(富山高専) M. Takada, Y. Hagino, | J. Asian Ceram. Soc., 9(2), 498-506 (2021) |

| 消波ブロック傾斜堤の性能評価におけるDupuit-Forchheimer則の適用 | 菊崎郁人・荒木進歩(大阪大),久保田真一,三井 順,渡部未樹久 | 土木学会論文集B2 (海岸工学) Vol.77,No.2 pp.739-744 |

| SPH法による津波越流時の防波堤背後の流動場とブロック挙動の数値解析 | 三井 順,久保田真一,松本 朗 | 土木学会論文集B2 (海岸工学) Vol.77,No.2 pp.757-762 |

| 遊水部を有する長周期波対策マウンドの消波特性に関する研究 | 三井 順,渡部未樹久,久保田真一,松本 朗 | 土木学会論文集B3 (海洋開発) Vol.77,No.2 pp.43-48 |

| Numerical investigation on effectiveness of portable rubble mound breakwater for mangrove restoration | S. Sreeranga・高木泰士・白井陸大(東工大),久保田真一,三井 順 | 土木学会論文集B3 (海洋開発) Vol.77,No.2 pp.61-66 |

| 低天端海洋構造物における消波工の断面形状の変化が波力低減効果に与える影響 | 澁谷容子・山本郁佳(東洋建設),荒木進歩(大阪大),久保田真一,小竹康夫(東洋建設) | 土木学会論文集B3 (海洋開発) Vol.77,No.2 pp.253-258 |

| サンゴ礁域における木材増殖礁の水産増殖効果 | 柴田早苗,幸田隆史・高山博史(神鋼建材工業),仲本豊(仲本工業),伊藤靖(漁村総研),末永慶寛(香川大) | 土木学会論文集B3 (海洋開発) Vol.77,No.2 pp.571-576 |

| 袋型根固め材周辺の浮遊砂堆積に関する数値解析 | 萩原照通,会田俊介・風間聡(東北大) | 第29回地球環境シンポジウム講演集,pp.167-172 |

| 浮遊砂が袋型根固め材周辺の河床洗堀に及ぼす影響について | 萩原照通,会田俊介・風間聡(東北大) | 土木学会年次学術講演会 (第76回) Ⅱ-32 |

| 越波実験による消波ブロックのroughness factorの算定及び波の遡上状況 | 渡部未樹久,久保田真一,三井 順,荒木進歩・菊崎郁人・渡邊真子(大阪大),渡邊大輝(大林組) | 土木学会年次学術講演会 (第76回) Ⅱ-88 |

| 物理エンジンを用いた消波ブロックの抵抗力評価手法の検討 | 三井 順,久保田真一,松本 朗 | 土木学会年次学術講演会 (第76回) Ⅱ-89 |

| 3次元データを活用した消波ブロックの数量算出法に関する基礎的検討 | 橋田雅也,昇 悟志,松本 朗 | 土木学会年次学術講演会 (第76回) Ⅵ-279 |

| 植生が繁茂した袋型根固め材の安定性について | 萩原照通,会田俊介・風間聡(東北大) | 令和3年度土木学会東北支部技術研究発表会,Ⅱ-28 |

| 消波ブロック傾斜堤の性能評価手法の高精度化への試み | 菊崎郁人・荒木進歩(大阪大),久保田真一,三井 順,渡部未樹久 | 混相流シンポジウム2021講演論文集 |

| Blind-test numerical simulation of tsunami wave pressure acting on a land structure | 三井 順,川崎浩司(ハイドロ総合技術研究所),久保田博貴(パシフィックコンサルタンツ),鈴木高二朗(港湾空港技術研究所) | Journal of Disaster Research Vol.16, No.7, pp.1005-1014 |

| Applicability of the numerical simulation of the impulsive wave pressure of solitary waves | 有川太郎(中央大),高橋研也(五洋建設),鈴木高二朗(港湾空港技術研究所),木原直人(電力中央研究所),岡本大史(中央大),三井 順 | Journal of Disaster Research Vol.16, No.8, pp.1286-1297 |

| SPH simulation of hydrodynamic behaivior of Tetrapods against solitary wave | 三井 順,C. ALTOMARE(カタルーニャ工科大学),A.J.C. CRESPO・J.M. DOMÍNGUEZ(ヴィーゴ大学),鈴木智弘(フランダース水理研究所),久保田真一,M. GÓMEZ-GESTEIRA(ヴィーゴ大学) | The 15th SPHERIC International Workshop, pp.38-44 |

| CI-CMC-HG工法(超硬質地盤に適応した大径深層混合処理工法) | 田中肇一,伊藤竹史,武田尚也 | 月刊「建設機械」2020年4月号 pp.68-72 |

| 細粒分混り砂の異方応力状態による液状化過程の損失エネルギー特性 | 石川敬祐(東京電機大),原田健二,安田進(東京電機大),出野智之,町田亘(東京電機大) | 第55回地盤工学研究発表会 21-2-2-01 |

| 細粒分を含む砂質土のN値と液状化強度に及ぼす水平応力比の影響 | 原田健二,石原研而(中央大),矢部浩史 | 第55回地盤工学研究発表会 21-11-2-04 |

| ソイルセメントにおける任意材齢強度と 28 日強度の関係 | 堀内滋人,村上恵洋,尾形太,出野智之,伊藤泰隆 | 第55回地盤工学研究発表会 2222-29-08 |

| セメントスラリーの流動性に対する水セメント比と温度の影響 | 村上恵洋,伊藤竹史 | 第55回地盤工学研究発表会 22-10-1-04 |

| 締固め方法が改良地盤の微視構造変化に及ぼす影響 | 江副哲,梅田洋彰,大谷順(熊本大),佐藤宇紘(熊本大),原田健二 | 第55回地盤工学研究発表会 22-10-1-06 |

| 撹拌翼先端の水空気吐出装置による深層混合改良体強度への影響 | 中野武大,村上恵洋,田中肇一 | 第55回地盤工学研究発表会 22-10-1-07 |

| 硬質地盤に対応した深層混合処理工法の開発 | 武田尚也,田中肇一,伊藤竹史,田中隼矢 | 第55回地盤工学研究発表会 22-10-4-07 |

| 締固め砂杭打設を模擬した水平地盤模型の振動台実験 | 日下部真佑,古関潤一(東大),原田健二 | 第55回地盤工学研究発表会 22-11-1-05 |

| 高強度地盤改良体に対するせん断波速度の調査と改良地盤の評価について | 髙山英作,中野佳輔(竹中土木),長田高(昭和試錐) | 第55回地盤工学研究発表会 23-2-2-02 |

| 循環型社会への貢献に取り組んだ締固め砂杭工法 | 矢部浩史,橋本則之,竹内秀克,尾形太 | 地盤工学会誌 2020年8月号 pp.21-24 |

| 粒子構造と粒子形状が液状化強度に及ぼす影響(その2) | 出野智之,原田健二,矢部浩史,江副哲,日下部真佑 | 土木学会年次学術講演会 (第75回) III-71 |

| 細粒分混り砂の異方応力状態における損失エネルギーと体積ひずみの関係 | 石川敬祐(東京電機大),原田健二,安田進(東京電機大),出野智之,町田亘(東京電機大) | 土木学会年次学術講演会 (第75回) III-74 |

| 細粒分を含む砂質土のqc値と液状化強度に及ぼす水平応力比の影響 | 原田健二,石原研而(中央大),矢部浩史 | 土木学会年次学術講演会 (第75回) III-114 |

| 締固め砂杭打設を模擬した振動台実験における応力ひずみ関係 | 日下部真佑,古関潤一(東大),原田健二 | 土木学会年次学術講演会 (第75回) III-119 |

| 深層混合処理工法における撹拌翼先端吐出の硬質地盤への効果 | 武田尚也,村上恵洋,田中肇一 | 土木学会年次学術講演会 (第75回) VI-140 |

| 締固め改良地盤における静止土圧係数の増加が液状化抵抗比に及ぼす影響 | 山下勝司,吉富宏紀,原田健二 | 日本建築学会2020年度日本建築学会大会(関東) pp.547-548 |

| エコガイアストンを利用した効果的な水硬性スラグコンパクションパイル工法 | 伊藤竹史,廣田義一,篠崎晴彦・太田哲郎(日本製鉄) | 水底質浄化技術協会誌「ヘドロ第137号」 pp.46-51 |

| Mechanism and future risk of slope instability induced by extreme rainfall event in Izu Oshima Island, Japan | 東畑郁生(関東学院大),後藤聡(山梨大),後藤茂(早稲田大),秋間健,田中隼矢,内村太郎(埼玉大),王功輝(京都大),山口弘志(中央開発㈱),青山翔吾(東京大) | Natural Hazards pp.501–530 |

| Mechanism of slope disaster caused by extreme rain-fall in Izu Oshima Island, Japan, and future safety judgement | 東畑郁生(関東学院大),秋間健,後藤聡(山梨大),後藤茂(早稲田大),田中隼矢,青山翔吾(基礎地盤コンサルタンツ) | World Landslide Forum 2020 Kyoto Japan pp.121-130 |

| 細粒分混り砂の異方応力状態における液状化強度特性と損失エネルギー | 町田亘・石川敬祐(東京電機大),原田健二,安田進(東京電機大),出野智之 | 2020GEO関東技術発表会 防災3-4 |

| 不動テトラの新しいICT地盤改良~自動打設技術とリモート立会い | 古庄哲士 | 土木施工 令和2年12月号 pp.68-71 |

| 打設角度が異なるSCP改良杭の砂地盤上の盛土の沈下挙動に関する遠心模型実験 | 李楊・北詰昌樹・高橋章浩(東工大),大林淳,原田健二 | 第14回地盤改良シンポジウム pp.137-142 |

| リサイクル材料を用いた締固め砂杭(サンドコンパクションパイル)工法 への取組み | 尾形太,橋本則之,伊藤竹史,竹内秀克,矢部浩史 | 第14回地盤改良シンポジウム pp.143-148 |

| 細粒分を含む砂のN 値と液状化強度に及ぼす水平応力比の影響 | 原田健二,石原研而(中央大学),矢部浩二 | 第14回地盤改良シンポジウム pp.487-492 |

| 日米の液状化予測と対策の改良効果についての考察 | 原田健二,Orense R. P.(Auckland University) | 第14回地盤改良シンポジウム pp.593-600 |

| 複数本の砂杭打設における水平応力の計測 | 原田健二,矢部浩史,橋本則之,伊藤竹史 | 日本地震工学会大会 B-3-5 |

| 液状化対策としての締固め施工時における周辺影響評価解析 | 竹内秀克,野田利弘(名古屋大),河村精一(基礎地盤コンサルタンツ),浅岡顕(地震予知総合研究振興会) | 地盤工学会誌 2021年2月号 pp.10-13 |

| Enhanced reactivity of dicalcium phosphate dihydrate with fluoride ions by coating with apatite nanoparticles | 岡嶌夏輝,袋布昌幹,豊嶋剛司(富山高専),髙田将文,萩野芳章 | Journal of Asian Ceramics Society, Vol. 9, No. 2, pp. 498-506 |

| 波浪による消波ブロックのロッキング衝突現象に関する実験的研究 | 昇 悟志,堀内滋人,三井 順,久保田真一,千々和伸浩・岩波光保(東工大) | 土木学会論文集B3 (海洋開発) (通常号)Vol.76,No.1 pp.33-45 |

| SPH法による消波ブロック群の移動解析の試み | 三井 順,久保田真一,松本 朗 | 土木学会論文集B2 (海岸工学) Vol.76,No.2 pp.823-828 |

| 消波工の断面変形に伴う越波特性の変化に関する実験的検討 | 久保田真一,松本 朗 | 土木学会論文集B3 (海洋開発) Vol.76,No.2 pp.91-96 |

| バージ船から投入された捨石の沈降・堆積過程に関する数値シミュレーション | 三井 順,田中真史,山崎真史,原 隆 | 土木学会論文集B3 (海洋開発) Vol.76,No.2 pp.504-509 |

| 個別のブロックの沈降・堆積挙動に基づく堆積形状予測シミュレーション | 田中真史,三井 順,川島麻由美,山崎真史,原 隆 | 土木学会論文集B3 (海洋開発) Vol.76,No.2 pp.558-563 |

| だるまカゴ護岸の安定性と砂浜地形変化 | 猿渡亜由未・小林正法・髙須賀啓孝(北海道大),小山裕文・高橋幹夫,山下孝行(北海道川崎鐵網),樋口益盛(トワロン),渡部靖憲(北海道大) | 土木学会論文集A2 (応用力学) Vol.76,No.2 pp.461-468 |

| 根固めブロック周辺の浮遊砂堆積を促す効果的な配置方法の提案 | 萩原照通,会田俊介・風間聡(東北大) | 土木学会論文集B1(水工学) Vol76,No.2 pp.1189-1194 |

| 根固め用袋材への浮遊砂堆積傾向に関する実験的研究 | 萩原照通,会田俊介・風間聡(東北大) | 土木学会年次学術講演会 (第75回) Ⅱ-07 |

| 根固め材の配置と周辺の河床洗堀傾向に関する研究 | 萩原照通,会田俊介・風間聡(東北大) | 令和2年度土木学会東北支部技術研究葉発表会講演概要集,Ⅱ-42 |

| CFD-DEM連成計算による流れ場における捨石の沈降挙動解析 | 三井 順,田中真史,山崎真史,原 隆 | 混相流シンポジウム2020講演論文集 |

| Evaluation of Hydraulic Performance of Wave Dissipating Block Using Porosity | 荒木進歩・渡邊大輝(大阪大),久保田真一,橋田雅也 | ICCE 2020 (国際海岸工学会議 (第37回) ) |

| An Experimental Study on the Stability of Filter Units on Rubble Mound Breakwater | Aye Nyein MON・青木伸一(大阪大),小山裕文,木下勝尊,梶原幸治・川村裕紀(キョーワ) | ISOPE 2020 (国際海洋極地工学会議(第30回) ) |

| Simulation of the Behaivior of Tetrapods against Solitary Wave Using DualSPHysics | 三井 順,久保田真一,A.J.C. CRESPO・J. DOMÍNGUEZ・M. GÓMEZ-GESTEIRA(ヴィーゴ大学),C. ALTOMARE(カタルーニャ工科大学),鈴木智弘(フランダース水理研究所) | The 5th DualSPHysics Users Workshop |

| 模型実験において鉱石モデルの揚鉱速度を計測するRFIDシステムの開発 | 菅章悟, 折田清隆(東京海洋大),谷和夫(東京海洋大),鈴木亮彦,田中肇一 | 第44回海洋開発シンポジウム |

| 砂杭打設の載荷履歴が液状化強度特性に及ぼす影響 | 武田尚也,原田健二,矢部浩史,中出雄也,古関潤一(東京大) | 2019年度土木学会国大会第74回年次学術講演会 |

| 静的締固め砂杭工法による単粒度砕石杭の液状化強度特性 | 朝妻涼,吉富宏紀,山下勝司,原田健二 | 日本建築学会 2019年度日本建築学会大会(北陸) |

| 粒子構造と粒子形状がひずみの発達過程と損失エネルギーに及ぼす影響 | 日下部真佑,出野智之,原田健二,矢部浩史,江副哲 | 2019年度土木学会全国大会 |

| エジェクター吐出方式深層混合処理工法による低変位施工 その2(配合設計) | 出野智之,村上恵洋,伊藤竹史 | 第54回地盤工学研究発表会 |

| 軟弱地盤改良工事における施工時調査による設計変更事例 | 田中隼矢,杉野秀一 | 第33回日本道路会議 |

| 直接基礎建物の深層混合処理工法による設計事例 | 山下勝司,吉富宏紀 | 2019年9月号基礎工 特集「建築物のための改良地盤の設計及び品質管理指針」の改訂 株式会社総合土木研究所 |

| 狭隘な山間部における砂防堰堤基礎の地盤改良 | 田口雄一,秋間健,鈴木雅晴,中島昭雄 | 基礎工(総合土木研究所) |

| 粒子構造と粒子形状が液状化強度と損失エネルギーに及ぼす影響 ―SCP工法による改良効果の視点から― | 原田健二,江副哲,矢部浩史,出野智之,日下部真佑 | 2019日本地震工学会研究発表会 |

| Observation on consolidation settlement of ground improved by Sand compaction pile and Prefabricated vertical drain applied Dhaka MRT Line 6 | 今井優輝,栗木実、奥田光秋、Shahjahan | The 4th International conference on Geotechnics for Sustainable Infrastructure Development (Geotec Hanoi 2019) |

| Effect of SCP improvement geometry on mitigation of liquefaction-induced embankment settlement (盛土の液状化被害軽減におけるSCPの幾何学的改良効果地震応答解析事例) | 原田健二,李楊・北詰昌樹・高橋章浩(東工大) | The 4th International conference on Geotechnics for Sustainable Infrastructure Development (Geotec Hanoi 2019) |

| 締固め砂杭による周辺地盤への変位影響と対策事例【建築工事など都市部】 | 出野智之,村上恵洋,雑賀光洋 | 基礎工 10月号(総合土木研究所) |

| 不動テトラのICT地盤改良 | 古庄哲士,今給黎健一 | 土木施工 編集部 |

| テオフィリンを配位子としたマイクロ粒子型パラジウム吸着剤 | 貝掛勝也(神奈川大学),高田将文,金仁華(神奈川大) | 第30回廃棄物資源循環学会 研究発表会,p.237 2019年9月19日(木)〜9月21日(土) |

| APPLICATION OF TRANSFORM REACTION OF DICALCIUM PHOSPHATE DIHYDRATE (DCPD) FOR ON-SITE REMEDIATION TO FLUORIDE-POLLUTED SOIL | Masamoto Tafu・Saki Nakada・Yuya Hata・Takeshi Toshima(富山高専),Masafumi Takada,Yoshiaki Hagino,Takaharu Matsuoka・ Yoshiki Shimizu(ダイキン工業) | Geo-Environmental Engineering 2019 Concordia University, Montreal, Canada, May 30-31, 2019 |

| Effect of fluorapatite (FAp) coating on transform reaction of dicalcium phosphate dihydrate (DCPD) to FAp | N. Okajima・M. Tafu・S. Takamatsu・T. Toshima(富山高専),M. Takada,Y. Hagino | The 2nd Global Forum on Advanced Materials and Technologies for Sustainable Development (GFMAT-2) and the 4th International Conference on Innovations in Biomaterials, Biomanufacturing and Biotechnologies July 21–26 in Toronto, Canada. |

| 狭隘なシールド坑内から泥水式推進機を分岐発進 -名古屋市下水道 ほのか雨水調整池流入管- | 河合克敏(名古屋市下水道局),植手照博(不動テトラ・徳倉・東海特別共同企業体ほのか雨水幹線作業所),西田 克司 | トンネルと地下 2020年2月号 株式会社 土木工学社 |

| 長周期波対策マウンド構造物の反射率推定式の提案 | 三井 順,長谷川巌(エコー),田中真史,松本 朗 | 土木学会論文集B2 (海岸工学) Vol.75,No.2 pp.787-792 |

| 消波工の空隙率が波高伝達率および反射率に及ぼす影響 | 荒木進歩・渡邊大輝(大阪大),久保田真一 | 土木学会論文集B2 (海岸工学) Vol.75,No.2 pp.793-798 |

| 津波の流れに対する被覆ブロックのイスバッシュ数に関する水理模型実験 | 三井 順,間辺本文(漁港新技術),大井邦昭(技研興業),岡野谷知樹(日本コーケン),平山隆幸(三省水工),松下紘資(日建工学),古市尚基・大村智宏(水工研) | 土木学会論文集B3 (海洋開発) Vol.75,No.2 pp.367-372 |

| 防波堤に設置した防波柵の伝達波低減効果とケーソン作用波力 | 三井 順,久保田真一,松本 朗,小山裕文,古路裕子・中口彰人(日本パーツセンター),楳田真也・斎藤武久(金沢大) | 土木学会年次学術講演会 (第74回) Ⅱ-111 |

| 津波越流に対する防波堤マウンド被覆ブロックの安定性に及ぼす津波波形の影響 | 三井 順,久保田真一,松本 朗 | 土木学会年次学術講演会 (第74回) Ⅱ-184 |

| サンゴ礁域における食物網の推定-その2- | 伊藤 靖(漁村総研),柴田早苗,當舎親典(漁村総研),完山 暢(水産土木建設技術センター) | 日本サンゴ礁学会大会講演要旨集 (第22回) |

| サンゴ礁の魚類の育成場としての機能 | 伊藤 靖(漁村総研),柴田早苗,深瀬一之(水産レポート) | 2019年度 日本水産工学会学術講演会講演要旨集 pp.19-20 |

| Stability of Armor Units Covering High-mound Composite Breakwaters Against Tsunami Overflow | 三井 順,久保田真一,松本 朗 | Coastal Structures Conference 2019 |

| Introduction of Wave-dissipating Block Technologies Developed in Japan and Dissemination Activities Abroad | 竹内聖一,冨永 準(三省水工),滝 泰臣(日建工学),高橋 世(消波根固ブロック協会) | PIANC Yearbook 2018, Technical Articles Japan 2018, pp.114-130 |

| Isoyake Recovery Technique using artificial substrata in Japan | 橋本 牧・間辺本文(漁港新技術),綿貫 啓(アルファ水工),林 裕一(岡部),細澤豪志(海中景観),岡重文久(海洋土木),権田泰之(木曽興業),伊藤勝一(三省水工),田島 武(神鋼建材),福井洋介(太平洋マテリアル),寺島知己(中山製鋼),西村博一(日建工学),城越徹矢(日本リーフ),青田 徹 | The International Conference on Fisheries Engineering 2019,P06 (poster) |

| 地盤改良によるK値増大を考慮した岸壁構造物の動的遠心模型実験 | 森鼻章治,高橋英紀,森川嘉之,高野大樹,斎藤智志,鈴木亮彦,今井優輝,一井康二 | 第43回海洋開発シンポジウム(2018) |

| 杭や鋼矢板の引抜き後の流動化砂の充填とその展望 | 今井優輝,高田英典,小林一男,永石雅大 | 第13回地盤改良シンポジウム 主催:(公社)日本材料学会 |

| グラベルコンパクションパイル工法により改良された硬質地盤の液状化強度の評価 | 原田健二,伊藤竹史,山下勝司,藤崎勝利,富樫昇,笹岡里衣(鹿島建設) | 第13回地盤改良シンポジウム 主催:(公社)日本材料学会 |

| バイブロを用いた起振時水圧計測による原位置液状化強度の評価手法の検討 | 山下勝司,鈴木亮彦,高田英典,中澤博志(防災科学技術研究所) | 第13回地盤改良シンポジウム 主催:(公社)日本材料学会 |

| Study on the change of micro structure in compacted sand using X-ray CT | 原田健二,江副哲,梅田洋影,佐藤宇紘,大谷順(熊本大学) | KGS&JGS Joint Workshop / Incheon / August 23-24, 2018 / Korea |

| 新船・新装置紹介 ぱいおにあ第30フドウ丸(サンドコンパクション船) | 高田英典 | 機関誌「作業船」(一般社団法人 日本作業船協会) |

| バイブロを用いた起振時水圧計測による原位置液状化強度の評価に向けた土槽実験 | 山下勝司,鈴木亮彦,高田英典,中澤博志(防災科学技術研究所) | 2018年地震工学シンポジウム |

| 揚鉱実験における鉱石モデルの移動速度を計測するためのRFIDシステムの有効性の検討 | 菅章悟,折田清隆(東京海洋大学),谷和夫(東京海洋大学),鈴木亮彦,田中肇一 | 第54回地盤工学研究発表会 |

| SCP 改良位置による液状化地盤の沈下抑制効果への影響に関するFEM解析 | 原田健二,李楊・北詰昌樹・高橋章浩(東工大),大林淳 | 第54回地盤工学研究発表会 |

| 振動式・静的締固め砂杭工法による大規模地盤改良工事(その3) ~事後ボーリングによる地盤強化対策効果の確認結果について~ | 尾形太,堀内滋人,藤井嵩大,広重敬嗣,吉田龍平 | 2019年度全国大会第74回年次学術講演会(土木学会) |

| 単純組成の溶液を用いたDCPD 粒子表面への前駆体相誘起によるフッ化物イオンとの反応性改善効果 | 岡嶌夏輝・袋布昌幹・高松さおり・豊嶋剛司(富山高専),高田将文,萩野芳章 | 公益社団法人日本セラミックス協会 2019年年会 |

| ふっ素汚染土壌の原位置不溶化を目的とした、リン酸カルシウム(DCPD)不溶化資材の反応性に及ぼす共存イオンの効果 | 中田沙紀・袋布昌幹(富山高専),萩野芳章,高田将文,松岡隆晴・清水義喜(ダイキン工業) | 第24回 地下水・土壌汚染とその防止対策に関する研究集会(2018年) |

| マウンド天端が干出する防波堤における被覆ブロックの耐津波安定性 | 三井 順,久保田真一,松本 朗 | "土木学会論文集B2 (海岸工学) Vol.74,No.2 pp.295-300" |

| 3Dデータを活用した消波工の設計および施工の効率化・高度化検討 | 昇 悟志,橋田雅也,萩原照通,富永柚香,山崎真史,前川裕之 | "土木学会論文集B3 (海洋開発) Vol.74,No.2 pp.1-6" |

| 防波堤に設置した津波減衰柵の性能に関する実験的研究 | 三井 順,久保田真一,松本 朗,小山裕文,古路裕子・中口彰人(日本パーツセンター),楳田真也・斎藤武久(金沢大) | "土木学会論文集B3 (海洋開発) Vol.74,No.2 pp.151-156" |

| 開口部を有する被覆ブロックの人工リーフにおける波浪安定性に及ぼす水深波長比の影響 | 中村英輔,三井 順,久保田真一,松本 朗 | "土木学会論文集B3 (海洋開発) Vol.74,No.2 pp.378-383" |

| 消波工の測量点群を用いた消波ブロックのソリッドモデリング技術 | 橋田雅也,昇悟志,前川裕之,山崎真史,柴田あずさ,富永柚香 | "北陸地方建設事業推進協議会 平成30年度建設技術報告会報文集 pp.42-44" |

| サンゴ礁域における食物網の推定 | 伊藤 靖(漁村総研),柴田早苗,當舎親典(漁村総研),完山 暢(水産土木建設技術センター) | 日本サンゴ礁学会大会講演要旨集 (第21回) |

| Stability Estimation Method for Armor Units for Breakwaters with Parapets against Tsunami Overflow | 三井 順,久保田真一,松本 朗 | ICCE 2018 (国際海岸工学会議 (第36回) ) |

| New Technologies of Concrete Blocks with Tsunami Protection and Long-Period Wave Absorption | 久保田真一,三井 順,田中真史,松本 朗 | 34th PIANC World Congress |

| Application technology of granule body as infilling material for ground improvement | Akira Ezoe,Kenji Harada,Jun Ohbayashi,Jun Otani | "2nd International Conference on Bio-based Building Materials & 1st Conference on ECOlogical valorisation of GRAnular and FIbrous materials pp.15-19" |

| Ground Improvement Technologies against Liquefaction in Japan | Kenji Harada | "Booklet for 2017 CE (Civil Engineer) Symposium, University of Tokyo, Session 2 pp.14-17" |

| SCPによる石炭灰の埋立処分工事の事例 | 中出雄也,山田清,尾形太,内山恭輔 | "第52回地盤工学研究発表会(名古屋) pp.637-638" |

| 現地発生土の改質による締固め砂杭工法の中詰め材再利用 | 矢部浩史,竹内秀克,今井優輝,岡有己 | 第52回地盤工学研究発表会(名古屋) |

| μフォーカスX線CTを用いた締固め砂杭造成過程における改良地盤内部構造の可視化 | 江副哲,大谷順,佐藤宇紘,宮崎公平,原田健二 | "第52回地盤工学研究発表会(名古屋) pp.719-720" |

| 異方圧密状態が液状化強度や損失・ひずみエネルギーに及ぼす影響 | 原田健二,安田進,石川敬祐 | "第52回地盤工学研究発表会(名古屋) pp.1531-1532" |

| バイブロを用いた起振時水圧計測による締固め改良地盤の評価 | 山下勝司,鈴木亮彦,竹内秀克,今井優輝 | "第52回地盤工学研究発表会(名古屋) pp.1633-1634" |

| 液状化対策として外周部に配置するグラベルコンパクションパイル(GCP)に用いる砕石材料についての考察 | 久保陽太郎,村上恵洋,沖田雅夫,小熊宏 | "第52回地盤工学研究発表会(名古屋) pp.1647-1648" |

| 浅層地盤の締固めに関する基礎的実験 | 深田久,今給黎健一,渡辺英次 | "第52回地盤工学研究発表会(名古屋) pp.1667-1668" |

| 地盤条件が懸濁型薬液注入の浸透性に及ぼす影響について | 矢部浩史,深田久 | "土木学会第72回年次学術講演会 pp.57-58" |

| "石炭灰埋立地盤に対する静的締固め工法の適用性(その2)~有効締固め係数および相対密度と液状化強度の関係について~" | 尾形太,鵜野雅明,市橋豊隆,喜多千砂子,広重敬嗣,西野日出樹 | "土木学会第72回年次学術講演会 pp.71-72" |

| 日米における液状化に対する締固め工法に関する考察―米国におけるCPTによるSCP工法の設計法の適用性― | 原田健二,野津光夫,新川直利,今林清秀 | "日本地震工学会第13回年次大会梗概集 P1-11" |

| "地盤改良施工管理システム「Visios-3D」(ビジオス・スリーディー)" | 深田久,岡戸雅則,秋間健 | "平成29年度建設施工と建設機械シンポジウム論文集・梗概集 pp.183-184" |

| 地盤改良を可視化する新たな施工管理システムの開発と適用事例 | 秋間健,岡戸雅則 | "土木建設技術発表会2017概要集 pp.41-44" |

| Development and improvement effectiveness of sand compaction pile method as a countermeasure against liquefaction | Kenji Harada,Jun Ohbayashi | "Soils and Foundations Vol.57 Issue6 pp.980?987" |

| 大規模土工事での地域配慮と早期開通への取組み | 塩川元章 | "土木施工 VOL.58,NO.5 pp.30-33" |

| "リン酸カルシウム(DCPD)資材の土壌中ふっ素化合物との反応性評価" | 中田沙紀,袋布昌幹,高松さおり,豊嶋剛司,山本桂一郎,萩野芳章 | "第23回地下水・土壌汚染とその防止対策に関する研究集会 pp30~32" |

| "Reactivity of dicalcium phosphate dihydrate with various fluoride compounds" | Saki Nakada,Masamoto Tafu,Yoshiaki Hagino,Saori akamatsu,Atsushi Manaka,Takeshi Toshima,Keiichiro Yamamoto | "15th Conference & Exhibition of the European Ceramics Society (ECerS2017) p.256" |

| 消波ブロック被覆堤の最下層に設置されるブロックに作用する上載荷重に関する実験的研究 | 昇 悟志,久保田真一,松本 朗,千々和伸浩・岩波光保(東工大) | "土木学会論文集B3 (海洋開発) (通常号)Vol.73,No.1 pp.43-55" |

| 津波の流れに対する被覆ブロックの安定性に関する検討 | 三井 順,久保田真一,松本 朗 | "土木学会論文集B2 (海岸工学) Vol.73,No.2 pp.1027-1032" |

| 粘り強い防波堤および海岸堤防の被覆工に関する現状の知見と課題 | 三井 順,久保田真一,松本 朗 | "土木学会論文集B3 (海洋開発) Vol.73,No.2 pp.1-6" |

| うねりに対する港内側没水型対策工の消波性能に関する検討 | 菅 章悟,三井 順,久保田真一,松本 朗 | "土木学会論文集B3 (海洋開発) Vol.73,No.2 pp.54-59" |

| フィルターユニットの拘束条件が耐波安定性に及ぼす影響 | 斎藤祐樹(関西エアポート),稲津百華・青木伸一(大阪大),久保田真一,梶原幸治(キョーワ) | "土木学会年次学術講演会 (第72回) Ⅱ-212号,pp.423-424" |

| 人工基質を用いた磯焼け対策の提案-植食動物の食害軽減- | 橋本 牧(漁港新技術),綿貫 啓(アルファ水工),斎賀守勝(海中景観研究所),権田泰之(木曽興業),伊藤勝一(三省水工),神野充輝(三柱),中西 敬(日建工学),青田 徹 | "平成29年度日本水産工学会学術講演会論文集 pp.58-61" |

| 漁港内水域等に設置した貝殻構造物による増殖効果 | 伊禮宙未・木代寛士・穴口裕司(海洋建設),青田 徹,伊藤 靖(漁村総研) | "平成29年度日本水産工学会学術講演会論文集 pp.66-69" |

| 港内反射波を効率的に消波するコンパクトな没水型対策工 | 久保田真一,松本 朗,錦織和紀郎,廣瀬紀一 | "北陸地方建設事業推進協議会 平成29年度建設技術報告会報文集 pp.52-55" |

| 防波堤の上部工形状が津波の越流とマウンド被覆ブロックの安定性に及ぼす影響 | 三井 順,久保田真一,松本 朗 | "電力土木No.392,2017年11月号 pp.161-164" |

| Numerical Analysis on Hydraulic Characteristics of Tsunami Overtopping Caisson Breakwaters | 三井 順,久保田真一,松本 朗,半沢 稔 | Coasts, Marine Structures and Breakwaters 2017 (第11回) |

| An Optimized Concrete Block for Sustainable Coastal Structures | 久保田真一,錦織和紀郎,昇 悟志,松本 朗 | Vietnam-Japan Workshop on Estuaries, Coasts and Rivers 2017 |

| New type sand compaction pile method for densification of liquefiable ground underneath existing structure | Masaki Kitazume,Akihiko Takahashi,Kenji Harada,Naotoshi Shinkawa | "Journal of Geo-Engineering Science 3 pp. 1-13" |

| Shaking table tests on mitigation of liquefaction vulnerability for existing embedded lifelines | Masahide Otsubo,Ikuo Towhata,Toshihiko Hayashida,Masato Shimura,Taro Uchimura,Bangan Liu,Damoun Taeseri,Bertrand Cauvin,Hadrien Rattez | "Soils and Foundations Volume 56, Issue 3 pp.348-364" |

| Shaking table tests on liquefaction mitigation of embedded lifelines by backfilling with recycled materials | Masahide Otsubo,IkuoTowhata,Toshihiko Hayashida,Bangan Liu,Shigeru Goto | "Soils and Foundations Volume 56, Issue 3 pp.365-378" |

| Post-liquefaction settlement analyses based on the volume change characteristics of undisturbed and reconstituted samples | Kenji Ishihara,Kenji Harada,W.F. Lee,C.C. Chan,A.M.M. Safiullah | "Soils and Foundations Volume 56, Issue 3 pp.545?558" |

| Advanced design of sand compaction pile as the liquefaction mitigation | Mitsuo Nozu,Naotoshi Shinkawa,Tooru Inoue | "The 3rd International Conference on Earthquake Engineering and Disaster Mitigation 2016 3rd ICEEDM-08" |

| 2流線吐出方式による高圧噴射撹拌工法の改良体の品質について | 秋間健,芝原久寛,田邊重雄,鈴木亮彦 | "第51回地盤工学研究発表会(岡山) pp.657-658" |

| 揺動式高圧噴射攪拌工法の供用中港湾施設直下への適用事例 | 高田英典,尾形太,米原吉彦,安達弘,有村充治 | "第51回地盤工学研究発表会(岡山) pp.799-800" |

| 台船を用いたエア・スラリー式高圧噴射撹拌工法の河川内工事への適用 | 杉本知弘,今井優輝,岡戸正則,田中肇一 | "第51回地盤工学研究発表会(岡山) pp.801-802" |

| エジェクター吐出方式深層混合処理工法による硬質地盤での大深度施工事例 | 久保陽太郎,鵜野雅明 | "第51回地盤工学研究発表会(岡山) pp.805-806" |

| 砂圧入式静的締固め工法における珪石粉配合率の比較 | 中出雄也,竹内秀克,鵜野雅明 | "第51回地盤工学研究発表会(岡山) pp.839-840" |

| 砂圧入式静的締固め工法の水中斜め施工適用事例 | 江副哲,酒井英之,竹内秀克,尾形太 | "第51回地盤工学研究発表会(岡山) pp.841-842" |

| 細粒分含有率を多く含む地盤における静的締固め砂杭工法の改良効果 | 出野智之,朝妻涼 | "第51回地盤工学研究発表会(岡山) pp.843-844" |

| 海上サンドコンパクションパイル改良地盤の応力特性についての考察 | 森鼻章治,秋間健,尾形太,竹内秀克,鈴木亮彦 | "第51回地盤工学研究発表会(岡山) pp.847-848" |

| 締固め砂杭工法によるN値増加の要因に関する考察 | 原田健二,大林淳,矢部浩史 | "第51回地盤工学研究発表会(岡山) pp.1697-1698" |

| 液状化に伴う残留変形評価法による締固め改良効果の評価事例 | 原田健二,石川敬祐,安田進,永井慎太郎 | "土木学会第71回年次学術講演会(平成28年9月) pp.437-438" |

| 仙台空港B滑走路における地盤改良工事の施工管理について | 高橋仁志,佐藤匡,金田豊,山岸真一,安藤滋郎 | "土木学会第71回年次学術講演会(平成28年9月) pp.505-506" |

| 相対密度の異なる飯豊珪砂の中空ねじりせん断試験による液状化強度特性 | 高山英作,古関潤一 | "土木学会第71回年次学術講演会(平成28年9月) pp.605-606" |

| A Case Study on Seismic Response Analysis on Improved Ground with Compaction | Kenji Harada,Nozomu Yoshida,Jun Ohbayashi,Shigeo Ando | "The 7th Taiwan-Japan - Taiwan Joint Workshop on Geotechnical Hazards from Large Earthquakes and Heavy Rainfall pp.69-70" |

| Verification of Improvement Effectiveness by Compaction Methods During the 2011 off the Pacific Coast of Tohoku Earthquake | Kenji Harada,Jun Ohbayashi,Yuichi Taguchi | "Geotechnical Hazards from Large Earthquakes and Heavy Rainfalls(Springler) pp.39-47" |

| 再現解析に基づいた締固めによる改良地盤の評価 | 原田健二,安田進,石川敬祐,大林淳,永井慎太郎 | "日本地震工学会第12回年次大会梗概集 P4-8" |

| 貫入/造成を伴う締固め工法の密度増大のメカニズムと改良効果についての考察 | 原田健二,大林淳,矢部浩史 | "第12回 地盤改良シンポジウム論文集 pp.235-242" |

| 揺動式複流線固化材スラリー噴射撹拌工法の既設構造物への適用事例 | 村上恵洋,伊藤竹史,秋間健 | "第12回 地盤改良シンポジウム論文集 pp.447-450" |

| 既設構造物直下の効率的な地盤改良 ―FTJ-FAN工法― | 伊藤竹史,杉野秀一,田口雄一 | "北陸地方建設事業推進協議会 平成28年度建設技術報告会 pp.53-56" |

| Construction Technology and Improvement Effectiveness of Sand Compaction Pile Method as Countermeasure against Liquefaction | Akira Ezoe,Kenji Harada,Mitsuo Nozu,Jun Otani | "The 8th Asian Joint Symposium on Geotechnical and Geoenvironmental Engineering JS-Tainan 2016 pp.165-170" |

| 扇形および矩形断面を造成できる高圧噴射攪拌工法の紹介- FTJ-FAN(エフティジェイファン)工法- | 深田久 | "平成28年度建設施工と建設機械シンポジウム「ポスターセッション発表」 pp.155-156" |

| Liquefaction perspective of soil ageing | Ikuo Towhata,Yuichi Taguchi,Toshihiko Hayashida,Shigeru Goto,Yuki Shintaku,Yuki Hamada,Shogo Aoyama | "Geotechnique pp.1-12" |

| 野蒜水門の災害復旧工事 | 淺田浩司 | "基礎工 Vol.44,No.8 pp.54~57" |

| "既存ゲートを活用した水門の復旧 -鳴瀬川野蒜水門災害復旧工事-" | 淺田浩司 | "土木施工 VOL.58,No.3 pp.48~51" |

| "覆工表層部の品質向上のために透水性シートを適用 -国道45号南三陸道路4号トンネル-" | 小林正和,伏見友宏,山中健大,小枝保彦 | "一般社団法人日本トンネル技術協会『トンネルと地下』 552号 Vol.47 No.8" |

| リン酸水素カルシウム二水和物によるふっ素汚染土壌の不溶化処理 | 松岡隆晴,清水義喜,萩野芳章,袋布昌幹 | "第22回地下水・土壌汚染とその防止対策に関する研究集会 pp123~127" |

| | |

| 没水型長周期波対策マウンド構造物の消波メカニズムに関する検討 | 三井 順,菅 章悟,久保田真一,松本 朗,半沢 稔 | "土木学会論文集B2 (海岸工学) Vol.72,No.2 pp.895-900" |

| 津波に対する防波堤背後の腹付工の滑動抵抗力の検討 | 三井 順,久保田真一,松本 朗,半沢 稔 | "土木学会論文集B2 (海岸工学) Vol.72,No.2 pp.1039-1044" |

| 防波堤港内側マウンド被覆ブロックの耐津波安定性に及ぼす上部工形状の影響 | 三井 順,久保田真一,松本 朗,半沢 稔 | "土木学会論文集B2 (海岸工学) Vol.72,No.2 pp.1111-1116" |

| 消波工の最下層に設置されるブロックに作用する上載荷重の特性 | 昇 悟志,久保田真一,松本 朗,千々和伸浩・岩波光保(東工大) | "土木学会論文集B3 (海洋開発) Vol.72,No.2 pp.I_235-I_240" |

| 震災で発生したコンクリートがらの漁場施設への適用性に関する研究 | 伊藤 靖(漁港漁場漁村技術研究所),不動雅之(水産庁),田中浩生,綿貫 啓(アルファ水工) | "水産工学 (第53巻第2号) pp.73-80" |

| 消波工の最下層に設置される消波ブロックの曲げ耐荷力評価に関する基礎的研究 | 昇 悟志,千々和伸浩・岩波光保(東工大) | "コンクリート工学年次論文集 Vol.38,No.2,pp.559-564" |

| 根固め用袋材周辺の河床変動に関する研究 | 萩原照通,会田俊介・風間聡(東北大) | "土木学会年次学術講演会 (第71回) Ⅱ-060号,pp.119-120" |

| 津波に対する防波堤背後の腹付工の効果に関する水理模型実験 | 三井 順,久保田真一,松本 朗 | "土木学会年次学術講演会 (第71回) Ⅱ-229号,pp.457-458" |

| 高波浪領域で使用される無筋コンクリート消波ブロックの曲げ耐荷力 | 昇 悟志,千々和伸浩・岩波光保(東工大) | "土木学会年次学術講演会 (第71回) Ⅴ-667号,pp.1333-1334" |

| 高波浪海域で使用される無筋消波ブロック-ドロスⅡ型- | 昇 悟志,錦織和紀郎,廣瀬紀一,浜口正志 | "北陸地方建設事業推進協議会 平成28年度建設技術報告会報文集 pp.109-112" |

| Estimation Method of Armor Stability against Tsunami Overtopping Caisson Breakwater Based on Overflow Depth | 三井 順,松本 朗,半沢 稔,灘岡和夫(東工大) | "Coaltal Engineering Journal, Vol.58, No.4, 1640019" |

| Estimation of Tsunami Force Acting on the Block Armored Breakwater Due to Soliton Fission | 丸山草平,髙山知司 (沿岸センター),下迫健一郎 (港空研),八尋明彦 (沿岸センター),鈴木高二朗(港空研),青田 徹,田中真史(沿岸センター),松本 朗,半沢 稔 | ICCE 2016 (国際海岸工学会議 (第35回) ) |

| Derivation Process of the Isbash Formula and Its Applicability to Tsunami Overtopping Caisson Breakwaters | 三井 順,松本 朗,半沢 稔 | International Conference on the Application of Physical Modelling in Coastal and Port Engineering and Science (第6回) |

| Recent Development of New Concrete Blocks in Japan | 松本 朗,半沢 稔,廣瀬紀一,久保田真一,昇 悟志,三井 順 | Vietnam-Japan Workshop on Estuaries, Coasts and Rivers 2016 |

| OUTLINE AND APPLICATION EXAMPLE OF DEEP MIXING MEETING HIGH QUALITY AND HIGH EFFICIENCY-EXECUTION | 森鼻章治,原田健二,鈴木亮彦,田邊重雄,竹内秀克,榊原優 | "Deep Mixing 2015 923-932" |

| SECURING OF IN-SITU CEMENT MIXING QUALITY FOR THE EXPANSIVE SOIL WITH THE ‘MONTMORILLONITE’ INCLUSION (モンモリロナイトを含む膨張性粘土の現地攪拌時の品質確保) | 野津光夫,榊原優,ゴアントゥン | Deep Mixing 2015 |

| 変位緩衝孔領域の締固め砂杭改良による性状変化と排土量の関係 | 佐藤希絵,今井優輝 | "第50回地盤工学研究発表会(札幌) 837-838" |

| 薬液注入材料の礫質地盤への適用性に関する基礎実験 | 深田久,渡辺英次,矢部浩史 | "第50回地盤工学研究発表会(札幌) 839-840" |

| ライムストーンと砂の混合地盤上の空港滑走路拡張工事におけるMVT(一定振動)による表層締固め | 野津光夫,松下和紀,松本淳之介 | "第50回地盤工学研究発表会(札幌) 841-842" |

| 浅海域における海上SCP工法の効率的な施工方法 | 尾形太,知念正吉,小西敦也,久野敦史 | "第50回地盤工学研究発表会(札幌) 853-854" |

| 砂圧入式静的締固め工法の施工域周辺における水質調査事例 | 森鼻章治,片山岳,竹内秀克,渡辺英次 | "第50回地盤工学研究発表会(札幌) 859-860" |

| エジェクター吐出式深層混合処理工法による供用中ガス導管近接施工時の鉛直変位計測例 | 秋間健,杉本知弘,今井優輝,熊勝則 | "第50回地盤工学研究発表会(札幌) 875-876" |

| 砂圧入式静的締固め工法における珪石粉混合材料による圧入効果 | 久保陽太郎,鵜野雅明,竹内秀克 | "第50回地盤工学研究発表会(札幌) 1843-1844" |

| 締固め砂杭工法の貫入/造成過程における密度増加に関する考察 | 原田健二,大林淳,矢部浩史 | "第50回地盤工学研究発表会(札幌) 1869-1870" |

| 供用中の空港における砂圧入式静的締固め工法の適用事例 | 高山英作,梅木洋人,高橋伸一,内生蔵一樹 | "第50回地盤工学研究発表会(札幌) 1879-1880" |

| 既設河川構造物の耐震化における揺動式高圧噴射攪拌工法の適用事例 | 伊藤竹史,高山英作,岡戸雅則,大竹洋,江川康夫 | "第50回地盤工学研究発表会(札幌) 1881-1882" |

| 東京国際空港C10誘導路における砂圧入式締固め工法の適用について | 杉本知弘,小松陽,清水勇,飯島遼,太田和行 | "第50回地盤工学研究発表会(札幌) 1891-1892" |

| 時間経過後の締固め砂杭改良地盤特性 | 林田敏彦,小松陽,田邊重雄,今井優輝 | "第50回地盤工学研究発表会(札幌) 1893-1894" |

| 砂地盤の締固めを目的とした海上SCP工法の改良効果 | 高田英典,尾形太,鈴木亮彦,竹内秀克 | "第50回地盤工学研究発表会(札幌) 1895-1896" |

| 縦ずれ断層変位に対する地表面変形低減手法に関する基礎的検討 | 田中隼矢,東畑郁生,Abbas Ghalandarzadeh | "第50回地盤工学研究発表会(札幌) 2033-2034" |

| 締固め砂杭工法によるN値増加に関する一考察 | 原田健二,大林淳,矢部浩史 | "土木学会第70回年次学術講演会 61-62" |

| 高速道路盛土基礎地盤への空気注入不飽和化工法適用性検討(その5)-現場実験結果と気液二相流解析の比較 | 矢部浩史,藤原斉郁,山根信幸,大石雅彦,中園康平,紙田直充,岡村未対 | "土木学会第70回年次学術講演会 69-70" |

| "Consideration on Liquefaction Resistance of Ground Improved by the Sand Compaction Pile Method(SCP工法により改良された地盤の液状化強度に関する考察)" | 原田健二,野津光夫,新川直利,松下和紀,榊原優 | "40th Annual Conference on Deep Foundations 381-390" |

| Evaluation example on effectiveness of countermeasures against liquefaction for residential land-Compaction and drainage methods- | 原田健二,安田進,石川敬祐,大林淳,松本淳之介,肥後成一 | "6th International Conference on Earthquake Geotechnical Engineering paper No.711" |

| Application of Mammoth Vibro-Tamper (MVT) for the shallow compaction at airport runway expansion project in Florida (ライムストーンと砂の混合地盤上の空港滑走路拡張工事におけるMVT(大型バイブロタンパー)の適用) | 野津光夫,榊原優,松下和紀 | "国際地盤工学会第15回アジア地域会議(福岡市) TC202-10" |

| New ground improvement technologies under restricted conditions in Japan | 原田健二,大林淳,本淳之介,久保陽太郎,秋間健 | "国際地盤工学会第15回アジア地域会議(福岡市) 1165-1170" |

| 液状化強度曲線の類型化と経験式の提案 | 三上武子,吉田望,原田健二 | "日本地震工学会論文集 第16巻,第1号(特集号) 10-18" |

| 撹拌翼取付け型比抵抗センサーを用いた深層混合処理施工の品質管理について | 白鳥翔太郎,山口博久,榎田実,福島宏明 | 平成27年度土木学会全国大会 第70回年次学術講演会 |

| ソリトン分裂津波に対する消波ブロック被覆堤の津波波力算定法に関する研究 | 丸山草平,髙山知司 (沿岸センター),下迫健一郎 (港空研),八尋明彦 (沿岸センター),鈴木高二朗(港空研),青田 徹,田中真史(沿岸センター),松本 朗,半沢 稔 | "土木学会論文集B2 (海岸工学) Vol.71,No.2 pp.265-270" |

| イスバッシュ式の導出過程と防波堤を越流する津波への適用性 | 三井 順,松本 朗,半沢 稔 | "土木学会論文集B2 (海岸工学) Vol.71,No.2 pp.1063-1068" |

| 防波堤を越流する津波の数値解析 | 三井 順,松本 朗,半沢 稔 | "土木学会論文集B2 (海岸工学) Vol.71,No.2 pp.1075-1080" |

| 人工リーフ変状連鎖に及ぼす砕波と設置位置の関係 | 中村英輔,野口賢二(国総研),岩佐隆広・二瓶 功・伊藤幸義(建技),諏訪義雄(国総研) | "土木学会論文集B2 (海岸工学) Vol.71,No.2 pp.1147-1152" |

| 越波水の打ち込みによる海岸鉄道の道床被害とその対策の検討 | 橋田雅也・木村克俊・越智聖志(室蘭工大),宮武 誠(函館高専),高橋幹夫,浜口正志 | "土木学会論文集B3 (海洋開発) Vol.71,No.2 pp.263-268" |

| 漁港防波堤の腹付マウンド被覆ブロックの津波越流に対する安定性の検討 | 三井 順,松本 朗,錦織和紀郎,橋本 牧(漁港新技術研究会) | "水産工学 (第52巻第2号) pp.113-117" |

| イスバッシュ式の導出過程について | 三井 順,松本 朗,半沢 稔 | "土木学会年次学術講演会 (第70回) Ⅱ-178号,pp.355-356" |

| 津波に対する防波堤背後の消波ブロックの滑動抵抗の検討 | 三井 順,丸山草平,松本 朗,半沢 稔 | "土木学会年次学術講演会 (第70回) Ⅱ-179号,pp.357-358" |

| 根固め用袋材が河床変動に及ぼす影響について | 萩原照通,会田俊介・風間 聡(東北大) | "土木学会東北支部技術研究発表会 (第52回) Ⅱ-5" |

| 多自然型護岸が水生昆虫群集相に与える影響 | 会田俊介(東北大),萩原照通,風間 聡・糠澤 桂(東北大) | "土木学会東北支部技術研究発表会 (第52回) Ⅶ-6" |

| 津波越流に対する防波堤マウンド被覆ブロックの所要質量算定法 | 三井 順,菅 章悟,丸山草平,青田 徹,松本 朗,錦織和紀郎 | "土木建設技術発表会2015概要集 pp.18-25" |

| Wave Force Reduction Effect of Wave-Dissipating Works against Tsunami with Soliton Fission | 丸山草平,髙山知司 (沿岸センター),下迫健一郎 (港空研),八尋明彦 (沿岸センター),鈴木高二朗(港空研),青田 徹,田中真史(沿岸センター),松本 朗,半沢 稔 | Coastal Structures & Solutions to Coastal Disasters Joint Conference 2015 |

| Numerical Analysis on Tsunami Overtopping Caisson Breakwaters and Stability of Armor Units | 三井 順,松本 朗,半沢 稔,灘岡和夫(東工大) | Coastal Structures & Solutions to Coastal Disasters Joint Conference 2015 |

| New Design Method of Armor Units Covering Rubble Mound of Composite Breakwater against Tsunami Overflow | 三井 順,松本 朗,半沢 稔,灘岡和夫(東工大) | PIANC Yearbook 2015 |

| Recent Advances in Coastal Structures in Japan | 半沢 稔,松本 朗,廣瀬紀一,田中真史,三井 順,丸山草平,菅 章悟 | Vietnam-Japan Workshop on Estuaries, Coasts and Rivers 2015 |

| Stability and Disaster Mitigation Effect of Wave-dissipating Concrete Blocks of Detached Breakwaters against Tsunami Wave | 半沢 稔,松本 朗 | "Handbook of Coastal Disaster Mitigation for Engineers and Planners, Elsevier, pp.325-348(書籍)" |

| Mechanisms of Damage to Coastal Structures due to the 2011 Great East Japan Tsunami | Jeremy D. Bricker (東北大),中山昭彦(建設工学研究所),高木泰士 (東工大),三井 順,三木朋広(神戸大) | "Handbook of Coastal Disaster Mitigation for Engineers and Planners, Elsevier, pp.385-415(書籍)" |

| Disturbance of Port Operations due to Long-Period Waves and Countermeasures Using Submerged Mound Structures | 田中真史,松本 朗,半沢 稔 | "Handbook of Coastal Disaster Mitigation for Engineers and Planners, Elsevier, pp.491-508(書籍)" |

| 平成23年東北地方太平洋沖地震でみられた締固め改良による地盤の変形抑止効果の検証 | 竹内秀克,野田利弘,中井健太郎,高稲敏浩 | "地盤工学会特別シンポジウム-東日本大震災を乗り越えて- pp.182-188" |

| 宅地地盤におけるグラベルドレーン工法の適用と改良効果の評価事例 | 原田健二,大林淳,吉富宏紀,安田進,石川敬祐,肥後成一 | "地盤工学会特別シンポジウム-東日本大震災を乗り越えて- pp.535-541" |

| 締固め地盤改良の改良効果へ与える既存杭の影響 | 田口智也,金子治,吉富宏紀 | "第49回地盤工学研究発表会(九州) pp.813-814" |

| 締固め改良埋立地の長継続時間地震動作用時挙動に関する数値解析 | 竹内秀克,野田利弘,中井健太郎 | "第49回地盤工学研究発表会(九州) pp.1525-1526" |

| 砂圧入式静的締固め工法の原位置調査結果と考察 | 鵜野雅明,竹内秀克,久保陽太郎 | "第49回地盤工学研究発表会(九州) pp.801-802" |

| 木曽川下流域河川堤防における砂圧入式静的締固め工法の適用事例 ?改良効果と施工データの考察? | 久保陽太郎,鵜野雅明,竹内秀克 | "第49回地盤工学研究発表会(九州) pp.789-790" |

| 静的締固め砂杭工法における杭間地盤と砂杭芯の相対密度についての考察 | 高山英作,中山兼一,宮崎琢人,原田健二 | "第49回地盤工学研究発表会(九州) pp.793-794" |

| SCP施工時の振動影響に関する一考察 | 木下洋樹,村上恵洋,田中克実 | "第49回地盤工学研究発表会(九州) pp.791-792" |

| 廃棄物地盤におけるグラベルセメントコンパクションパイル工法の工事報告 | 深谷幸寛,内村徳康,久保陽太郎,中出雄也 | "第49回地盤工学研究発表会(九州) pp.815-816" |

| 砂圧入式静的締固め工法における施工時圧入量と設計値の比較 | 森鼻章治,竹内秀克,新川直利,大林淳 | "第49回地盤工学研究発表会(九州) pp.795-796" |

| 砂圧入式静的締固め工法の空港耐震化工事への適用性について | 杉本知弘,小松陽,鈴木亮彦,竹内秀克 | "第49回地盤工学研究発表会(九州) pp.797-798" |

| エジェクター吐出式深層混合処理工法の改良体品質に関する一考察 | 出野智之,村上恵洋,田中克実 | "第49回地盤工学研究発表会(九州) pp.13-14" |

| セメント系地盤改良に対するせん断波速度の調査と改良地盤の評価について | 樋口良,村上恵洋,田中克実,江副哲,武田尚也 | "第49回地盤工学研究発表会(九州) pp.635-636" |

| 新門司沖土砂処分場の延命化対策を目的としたフロート式プラスチックボードドレーン工法の適用事例 | 江副哲,池田秀文,永吉貴行,鳥原守,尾形太 | "第49回地盤工学研究発表会(九州) pp.807-808" |

| 伊豆大島における台風26号災害での崩壊土と非崩壊土の土質物理試験結果の比較 | 秋間健,東畑郁生,内村太郎,王功輝,衛藤一平 | "第49回地盤工学研究発表会(九州) pp.1833-1834" |

| 液状化被害低減工法における沈下量に関する研究 | 平田裕一,高橋直樹,宮田勝利,高岡雄二,大林淳,原田健二,鈴木亮彦,吉富宏紀,秋間健,東畑郁生 | "第49回地盤工学研究発表会(九州) pp.1609-1610" |

| 地盤改良の幾何学形状が液状化地盤上の盛土の応答に与える影響 | 佐藤直哉,大林淳,原田健二,北詰昌樹,高橋章浩 | "第49回地盤工学研究発表会(九州) pp.1365-1366" |

| 実地震における改良地盤についての再現解析 | 安田進,原田健二,石川敬祐,肥後成一 | "第49回地盤工学研究発表会(九州) pp.1909-1910" |

| 圧入による密度増加に物理特性が及ぼす影響 | 安田悟,規矩大義,山口恵美,石綿洸希,相馬佳奈美,原田健二,大林淳,竹内秀克 | "第49回地盤工学研究発表会(九州) pp.1593-1594" |

| A comparison between performance of sheet-pile walls against liquefaction-settlement of structures in 2-D and 3-D experiments | Rouzbeh Rasouli,秋間健,東畑郁生 | "第49回地盤工学研究発表会(九州) pp.1949-1950" |

| 変位緩衝孔打設域での締固め砂杭改良地盤の性状 | 佐藤希絵,今井優輝,岩田雄太郎 | "第49回地盤工学研究発表会(九州) pp.799-800" |

| 注入材料の礫質地盤への適用性に関する室内試験 | 深田久,渡辺英次,矢部浩史 | "第49回地盤工学研究発表会(九州) pp.821-822" |

| 空気注入不飽和化工法の高速道路盛土への適用性検討(その1)概要 | 内田純二,青木智幸,山根信幸,深田久,大内正敏,橋本欣也,岡村未対 | "第49回地盤工学研究発表会(九州) pp.1353-1354" |

| 空気注入不飽和化工法の高速道路盛土への適用性検討(その2)予備実験 | 藤井直,小林真貴子,居場博之,深田久,中園康平,江川元幾,岡村未対 | "第49回地盤工学研究発表会(九州) pp.1355-1356" |

| 空気注入不飽和化工法の高速道路盛土への適用性検討(その3)本実験計画と準備 | 居場博之,高畑陽,矢部浩史,大石雅彦,橋本 欣也,紙田直充,岡村未対 | "第49回地盤工学研究発表会(九州) pp.1357-1358" |

| 空気注入不飽和化工法の高速道路盛土への適用性検討(その4)本実験結果 | 藤原斉郁,冨田雄一,岡村未対,御手洗義夫,矢部浩史,藤井直,中園康平 | "第49回地盤工学研究発表会(九州) pp.1359-1360" |

| MEASURES DEVELOPED IN JAPAN AFTER THE 1964 NIIGATA EARTHQUAKE TO COUNTER THE LIQUEFACTION OF SOIL | 原田健二,安田進 | "Tenth U.S. National Conference on Earthquake Engineering Frontiers of Earthquake Engineering,Anchorage, Alaska CD-ROM" |

| Verification of improvement effectiveness by compaction methods during the 2011 off the Pacific Coast of Tohoku Earthquake | 原田健二,大林淳,田口雄一 | "The Sixth Japan - Taiwan Joint Workshop on Geotechnical Hazards from Large Earthquakes and Heavy Rainfall pp.73-74" |

| 液状化強度曲線の類型化と経験式の提案(その2) | 原田健二,三上武子,吉田望 | "2014年土木学会研究発表会 pp.61-62" |

| 締固めによる改良地盤におけるCPTによる指標Icについての考察 | 原田健二,野津光夫,新川直利 | "2014年土木学会研究発表会 pp.135-136" |

| 高速道路盛土への空気注入不飽和化工法の適用性検討(その1)概要 | 内田純二,紙田直充,青木智幸,山根信幸,深田久,大内正敏,橋本欣也,岡村未対 | "2014年土木学会研究発表会 pp.153-154" |

| 格子状改良による改良地盤の等価S波速度の評価(その1 設計概要) | 山縣信一郎,片岡達也,大西智晴 | "2014年日本建築学会大会 pp.577-578" |

| 格子状改良による改良地盤の等価S波速度の評価(その2 施工,検証) | 山縣信一郎,片岡達也,武田尚也,田中均 | "2014年日本建築学会大会 pp.579-580" |

| 建物外構部の液状化被害低減工法に関する振動台実験(その3) | 高岡雄二,宮田勝利,高橋直樹,平田裕一,原田健二,吉富宏紀,東畑郁生 | "2014年日本建築学会大会 pp.665-666" |

| 浅層盤状改良工法による戸建て住宅の液状化被害軽減効果の検証と経済性評価 | 谷和夫,松下克也,橋本隆雄,山本彰,竹内秀克,野田利弘,規矩大義,大林淳,清田隆 | "地盤工学ジャーナル Vol.9, No.4 pp.533-553" |

| 地震応答解析による締固め改良効果の評価事例 | 原田健二,吉田望,安藤滋郎 | "日本材料学会 第11回地盤改良シンポジウム pp.207-214" |

| エジェクター吐出式深層混合処理工法の改良体品質分析 | 村上恵洋,田中克実,出野智之 | "日本材料学会 第11回地盤改良シンポジウム pp.377-380" |

| 低改良率セメントコラム工法(ALiCC工法)の施工事例について | "近藤益央,宮武裕昭,宮川智史,大林淳,新川直利,柳浦良行,森田博夫" | "日本材料学会 第11回地盤改良シンポジウム pp.305-312" |

| 砂の液状化抵抗が年代とともに増加する現象について | 林田敏彦,田口雄一,東畑郁生,濱田悠貴,青山翔吾,後藤茂 | "第14回日本地震工学シンポジウム pp.2311-2320" |

| 締固め工法の密度増加のメカニズムと改良効果に関する考察 | 原田健二,大林淳,矢部浩史 | "第14回日本地震工学シンポジウム pp.2403-2412" |

| 液状化強度曲線の類型化と実験式の提案 | 原田健二,三上武子,吉田望 | "2014年地震工学シンポジウム pp.2419-2426" |

| Mitigation of seismic settlement of light surface structures by installation of sheet-pile walls around the foundation | Rouzbeh Rasouli,東畑郁生,林田敏彦 | "Soil Dynamics and Earthquake Engineering 72 pp.108-118" |

| "盛土施工における締固め特性について(2) ~大型無振動締固め機械による締固め特性~" | 永井裕之,茂木正晴,橋本毅,山下章,山口達也,松尾健二 | "土木学会第69回年次学術講演会 3-687 " |

| "盛土施工における締固め特性について(4)~施工機械の違いによる適用性~" | 古屋弘,茂木正晴,橋本毅,小薬はるな,黒台昌弘,小林純 | "土木学会第69回年次学術講演会 3-692" |

| 防音パネルとANC装置を併用した重機騒音の低減効果 | 小林純,山口博久,船田哲人,前川裕之 | "土木学会第69回年次学術講演会 7-79 " |

| "小土かぶり未固結地山の扁平大断面トンネルを中央導坑により掘削 -国道1号笹原山中バイパス2号トンネル-" | 毛利勇,遠藤拓二,山田勝己,船田哲人 | "トンネルと地下 vol.45 no.8 pp.7-15" |

| "SOCIAL REQUIREMENTS AND LANDFILL SITE STRUCTURE AS SEEN FROM THE CONSTRUCTION CASE OF JAPAN" | Toshinori Ichimaru,Ryoji Matsumoto,Takumi Tsuji,Toru Furuichi,Masataka Hanashima | APLAS Ho Chi Minh 2014 |

| フッ素汚染土壌の原位置不溶化 | 萩野芳章,清水義喜,石田大介,松岡隆晴,石井誠郎,袋布昌幹 | "第20回地下水・土壌汚染とその防止対策に関する研究集会 pp483~487" |

| 形質変更時要届出区域における汚染土壌の原位置不溶化事例 | 萩野芳章,清水義喜 | "基礎工2014.8月特集号 pp63~66" |

| フッ素汚染土壌の現位置不溶化に用いるリン酸カルシウム塩適応条件検討 | 袋布昌幹,間中淳,豊嶋剛司,清水義喜,石田大介,松岡隆晴,石井誠郎,萩野芳章 | "第11回地盤改良シンポジウム pp.37~42" |

| ソリトン分裂津波に対する消波工の波力低減効果に関する研究 | 丸山草平,髙山知司 (沿岸センター),下迫健一郎 (港空研),八尋明彦・青田 徹 (沿岸センター),松本 朗,半沢 稔 | "土木学会論文集B2 (海岸工学) Vol.70,No.2pp.781-785" |

| 数値解析に基づくケーソン背後の津波越流の再現と被覆材の安定性の検討 | 三井 順,松本 朗,半沢 稔,灘岡和夫 (東工大) | "土木学会論文集B2 (海岸工学) Vol.70,No.2pp.921-925" |

| 環境共生機能に配慮した新型ブロックの効果検証現地調査 | 廣瀬紀一,柴田早苗,若林信孝,昇 悟志,三井 順,浜口正志 | "土木学会論文集B3 (海洋開発) Vol.70,No.2pp.1050-1155" |

| 津波越流時の防波堤マウンド被覆石の安定性評価におけるイスバッシュ式の適用性 | 三井 順,松本 朗,半沢 稔 | "土木学会年次学術講演会 (第69回)Ⅱ-027号,pp.53-54" |

| 漁港防波堤の腹付マウンド被覆ブロックの津波越流に対する安定性の検討 | 三井 順,松本 朗,錦織和紀郎,橋本 牧(漁港新技術研究会) | 平成26年日本水産工学会秋季シンポジウム |

| Efficient Long-Period Wave Absorbing Submerged Mound Structure | 田中真史,松本 朗,半沢 稔 | ICCE 2014 (国際海岸工学会議 (第34回) ) |

| Stability of Armor Units Covering Rubble Mound of Composite Breakwaters against Steady Overflow of Tsunami | 三井 順,松本 朗,半沢 稔,灘岡和夫 (東工大) | ICCE 2014 (国際海岸工学会議 (第34回) ) |

| Armor Damage on Harbor Side Rubble Mound of Composite Breakwaters against Water Jet Caused by Impinging Bore-Like Tsunami | 丸山草平,三井 順,松本 朗,半沢 稔 | ICCE 2014 (国際海岸工学会議 (第34回) ) |

| A New Eco-Friendly Wave-Dissipating Concrete Block and Verification of Its Effectiveness from Field Observations | 廣瀬紀一,柴田早苗,西脇一郎,昇 悟志,中村英輔,三井 順 | ISOPE 2014 (国際海洋極地工学会議(第24回) ) |

| Advanced Concrete Block Technology in Japan | 半沢 稔,松本 朗,廣瀬紀一,田中真史,三井 順,丸山草平 | 19th IAHR-APD Congress 2014 |

| Resilient Structure of Composite Breakwater from the Viewpoint of Stability of Armor Units Covering Rubble Mound against a Steady Overflow of Tsunami | 半沢 稔,松本 朗,三井 順,丸山草平 | International Innovation Workshop on Tsunami, Snow Avalanche and Flash Flood Energy Dissipation |

| Performance Design for Maritime Structures | 半沢 稔,高橋重雄・下迫健一郎(港空研) | "Design of Coastal Structures and Sea Defenses, World Scientific,pp.77-104(書籍)" |

| "宅地地盤の液状化対策工法の開発と適用 一小型締固め式グラベルドレーンエ法-" | 原田健二,大林 淳,吉冨宏樹 | 地盤工学会誌,61-4(663),pp.22-25. |

| "DEFORMATION BEHAVIOUR OF GROUND IMPROVED BY SCP METHOD USING SOLIDIFIED IRON-AND-STEEL SLAG" | Hidenori Takahashi,Yoshiyuki Morikawa,Haruhiko Shinozaki,Hiroki Kinosita,Kenji Maruyama | 18th Southeast Asian Geotechnical & Inaugural AGSSEA Conference,pp.3713-3720 |

| "PROTECTION OF UNDEARGROUND LIFELINE FROM SEISMIC LIQUEFACTION PROBLEMS" | "Ikuo Towhata,Masahide Ohtubo,Taro Uchimura,Masato Shimura,Liu Bangan Toshihiko Hayashida" | The 5th International Geotechnical Symposium-Inchon,pp.22-24 |

| "SHAKING MODEL TESTS ON LIQUEFACTION MITIGATION OF EMBEDDED LIFELINE" | "Ikuo Towhata,Masahide Ohtubo,Taro Uchimura,Masato Shimura,Bangan Liu Toshihiko Hayashida,Damoun Taeseri,Bertrand Cauvin" | International Conference on Earthquake Geotechnical Engineering |

| ゆるい砂地盤における砂圧入締固めによる周辺地盤への3次元影響評価解析 | 竹内秀克,河村精一,野田利弘,浅岡 顕 | 地盤工学ジャーナル,Vol.8,No.2,pp.239-249. |

| 砂圧入式静的締固め施エにおける地盤条件の影響に関する土槽実験 | 竹内秀克,大林 淳,深田 久,渡辺英次,中嶋嘉孝 | 第48回地盤工学研究発表会(富山),pp.929-930 |

| 庄内川河川堤防における砂圧入式静的締固め工法の適用事例 | 鵜野雅明,竹内秀克,久保陽太郎,中出雄也 | 第48回地盤工学研究発表会(富山),pp.931-932 |

| 砂圧入式静的締固め工法の改良効果と各種施工データの考察 | 久保陽太郎,深田 久,鵜野雅明,竹内秀克 | 第48回地盤工学研究発表会(富山),pp.933-934 |

| 静的締固め砂杭工法の造成時押力について | "武田尚也,大林 淳,吉冨宏樹,吉浦彰洋 NaoyaTakeda,JunOhbayashi,HirokiYoshitomi," | 第48回地盤工学研究発表会(富山),pp.941-942 |

| 揺動式高圧噴射撹拌工法による基礎杭背面への廻り込みに関する考察 | 鈴木亮彦,大林 淳,原田健二,竹内秀克 | 第48回地盤工学研究発表会(富山),pp.955-956 |

| 宅地地盤の液状化対策についての模擬解析 | 吉富宏紀,原田健二,大林 淳,安田 進,石川敬祐,小澤直輝 | 第48回地盤工学研究発表会(富山),pp.1747-1748 |

| 宅地地盤における被災建屋の再現解析 | 安田 進,石川敬祐,小澤直輝,原田健二,吉富宏紀,大林 淳 | 第48回地盤工学研究発表会(富山),pp.1749-1750 |

| 液状化被害低減工法に関する研究 | "平田裕一,高橋直樹,宮田勝利,高岡雄二,大林 淳原田健二,鈴木亮彦,吉富宏紀,林田敏彦,東畑郁生" | 第48回地盤工学研究発表会(富山),pp.1755-1756 |

| 埋設管路の液状化被害軽減に関する実験 -浮上防止治具の適用- | 大坪正英.LiuBangan,林田敏彦,後藤 茂,東畑郁生 | 第48回地盤工学研究発表会(富山),pp.1773-1774 |

| 埋設管路の液状化被害軽減に関する実験-リサイクル材料による埋戻し- | 林田敏彦,大坪正英,LiuBangan,MinhLe’Ngoc,GabrielSimi,後藤 茂,東畑郁生 | 第48回地盤工学研究発表会(富山),pp.1775-1776 |

| Mitigation of liquefaction-induced damage on lifeline: Drainage methods | Liu Bangan,Masahide Ohtubo,Toshihjko Hayashida,Gabriel Simi,Ikuo Towhata | 第48回地盤工学研究発表会(富山),pp.1819-1820 |

| Effects of viscous liquid instead of water in model experiments on mitigation of liquefaction-induced subsidence of structures | Rouzbeh Rasouri,Ikuo Towhata,Toshihiko Hayashida | 第48回地盤工学研究発表会(富山),pp.1821-1822 |

| 攪乱・不攪乱試料に基づく液状化による体積変化特性 | 石原研而,原田健二,酒井運雄 | 第48回地盤工学研究発表会(富山),pp.1865-1866 |

| 建物外構部の液状化被害低減方法に関する振動台実験(その1) | 吉富宏紀,原田健二,宮田勝利,高岡雄二,瀬藤慎一,東畑郁生 | 日本建築学会大会学術講演会梗概集(北海道),pp.627-628 |

| 建物外構部の液状化被害低減方法に関する振動台実験(その2) | 高岡雄二,高橋直樹,平田裕一,鈴木亮彦,吉富宏紀,東畑郁生 | 日本建築学会大会学術講演会梗概集(北海道),pp.629-630 |

| 静的締固め砂杭工法のしらす地盤における改良効果(その1:設計概要と調査結果) | 鏑流馬久明,依田博基,原田健二,大西智晴 | 日本建築学会大会学術講演会梗概集(北海道),pp.729-730 |

| 静的締固め砂杭工法のしらす地盤における改良効果(その2:K0増加の液状化強度に及ぼす影響) | 原田健二,大西智晴,依田博基,鏑流馬久明 | 日本建築学会大会学術講演会梗概集(北海道),pp.731-732 |

| 静的締固め砂杭工法の動的挙動と改良効果(その3:締固め改良幅が及ぼす影響) | 武田尚也.鏑流馬久明,井上 啓,大西智晴 | 日本建築学会大会学術講演会梗概集(北海道),pp.733-734 |

| 打戻し式SCP工法によるシルト層の地盤改良効果の確認 その2 原位置試験,室内試験結果 | 鵜野雅明,大久保浩光,鈴木 陽,坪井利弘,都築充雄,舘 雄二 | 日本建築学会大会学術講演会梗概集(北海道),pp.741-742 |

| 軟弱地盤における積載荷重の大きな土間への静的締固め固化改良工法の適用 | 佐藤光浩,山崎勉,八重樫光,吉富宏紀 | 日本建築学会大会学術講演会梗概集(北海道),pp.745-746 |

| 撹乱・不撹乱試料に基づく簡易な液状化による沈下予測法 | 原田健二,石原研而 | 土木学会第68回年次学術講演会,pp.107-108 |

| 比抵抗変化率による空気注入中の飽和度の推定 | 居場博之,山根伸幸,新川直利,大内正敏,山田直之,岡村未対 | 土木学会第68回年次学術講演会,pp.161-162 |

| 砂圧入式静的締固め工法による地盤の密度増加に関する基礎実験 | 規矩大義,山口恵美,原田健二 | 土木学会第68回年次学術講演会,pp.185-186 |

| 供試体条件の違いによる砂質土の液状化強度に与える細粒分含有率の影響 | 中澤博志,原田健二 | 土木学会第68回年次学術講演会,pp.643-644 |

| シース管挿入による既設埋設管継手の耐震補強~液状化土砂の流入防止~ | 大坪正英,林田敏彦,志村雅仁,東畑郁生 | 土木学会第68回年次学術講演会,pp.677-678 |

| 種々な地盤材料の液状化特性に関する考察 | 石川敬祐,安田 進,原田健二 | 第33回地震工学研究発表会,7P |

| 簡易な液状化後の沈下予測法に基づく締固めによる地盤改良効果 | 原田健二,石原研而 | 第33回地震工学研究発表会,2P |

| SHAKING TABLE TESTS ON MITIGATION OF LIQUEFACTION DAMAGE TO EMBEDDED LIFELINE BY CHEMICAL GROUTING METHOD | "Masahide Ohtubo,Bertrand Cauvin,Masato Shimura,Shogo Aoyama,Takeshi Akima Ikuo Towhata,Taro Uchimura,Hardren Rattez" | International Symposium on Earthquake Engineering,JAEE,Vol.2,pp.161-170 |

| 3-D EXPERIMENTS ON PERFORMANCE OF MITIGATIONS AGAINST LIQUEFACTION-INDUCED SUBSIDENCE OF SURFACE STRUCTURES | Rouzbeh Rasouli,Takeshi Akima,Valeria Awad,Sunshine Tan,IkuoTowhata | International Symposium on Earthquake Engineering,JAEE,Vol.2,pp.171-176 |

| VERIFICATION OF EFFECTIVENESS OF LIQUEFACTION COUNTERMEASURES DURING PAST LARGE SCALE EARTHQUAKES IN JAPAN | Kerdi Harada,Jun Ohbayashi,Junnosuke Matsumoto,Hiroki Yoshitomi,Susumu Yasuda,Rolando Orense | NewZealand-Japan Workshop on Soil Liquefaction during Recent Large-Scale Earthquake,pp.181-185 |

| 振動ローラ加速度応答法による盛土締固めの品質管理への適用(粗粒材料を対象とした大型土槽実験) | 中村洋丈,藤岡一頼,古屋弘,内山恵一,松本江基,浅田浩司 | 平成25年度建設施工と建設機械シンポジウム論文集・梗概集 |

| 防波堤港内側マウンド被覆材の津波越流に対する安定性照査方法の提案 | 三井 順,松本 朗,半沢 稔,灘岡和夫 (東工大) | "土木学会論文集B2 (海岸工学) Vol.69,No.2 pp.956-960" |

| 袋型根固め材を用いた津波に対して効果的な防波堤マウンド被覆方法の検討 | 三井 順,松本 朗,半沢 稔,小山裕文,篠村幸廣・尾池宣佳 (キョーワ) | "土木学会論文集B3 (海洋開発) Vol.69,No.2 pp.479-484" |

| 混成堤背面に適用した没水型長周期波対策マウンド構造物の越波に対する安定性 | 田中真史,松本 朗,半沢 稔 | "土木学会論文集B3 (海洋開発) Vol.69,No.2 pp.664-669" |

| 海岸鉄道の高波による運行障害事例とその対策に関する検討 | 平野夕焼 (東亜建設),木村克俊・越智聖志 (室蘭工大),高橋幹夫,浜口正志 | "土木学会論文集B3 (海洋開発) Vol.69,No.2 pp.688-693" |

| 環境共生に配慮した新型消波ブロックの開発と現地調査による効果検証 | 廣瀬紀一,柴田早苗,西脇一郎,昇 悟志,中村英輔,三井 順 | "地球環境シンポジウム講演集 (第21回) pp.201-206" |

| 津波に対する防波堤港内側マウンドの保護工法 | 松本 朗,三井 順,錦織和紀郎,日名敏泰,浜口正志 | "北陸地方建設事業推進協議会 平成25年度建設技術報告会報文集(CD-ROM) pp.87-90" |

| 防波堤港内側マウンド被覆材の津波越流に対する安定性の検討 -コンクリートブロックの所要質量算定方法の提案- | 三井 順,松本 朗,半沢 稔 | "電力土木No.368,2013年11月号 pp.132-134" |

| 防波堤直立壁の表面形状が与えるサンゴの着生効果(その2)-10年にわたる調査結果- | 廣瀬紀一,柴田早苗,青田 徹,口ノ町誠,谷口洋基 (阿嘉島臨海研究所) | "日本サンゴ礁学会第16回大会講演要旨集p.35" |

| 防波堤背面に設置した没水型長周期波対策工の津波越流に対する安定性 | 三井 順,田中真史,松本 朗,半沢 稔 | "土木学会年次学術講演会 (第68回)Ⅱ-169号,pp.337-338" |

| 消波工の津波力低減効果に関する検討 | 丸山草平,三井 順,松本 朗,半沢 稔 | "土木学会年次学術講演会 (第68回)Ⅱ-170号,pp.339-340" |

| 没水型長周期波対策工の消波特性に関する計算 | 松本 朗,田中真史,半沢 稔 | "土木学会年次学術講演会 (第68回)Ⅱ-204号,pp.407-408" |

| 消波ブロックの形状特性と景観(調和感)に関する評価手法の検討 | 萩原照通,袖山和志,柴田あずさ | "土木学会年次学術講演会 (第68回)Ⅱ-205号,pp.409-410" |

| New Fish Reef Block Ensuring Accurate Placement by Free-Fall Method | 三井 順,灘岡和夫 (東工大),緒方信一,柴田早苗,山本方人 (三柱),松本 朗 | "Journal of Waterway, Port, Coastal, and Ocean EngineeringVolume 139, Number 6 pp.455-465" |

| A Submerged Mound Type Long-Period Wave Absorbing Structure | 田中真史,松本 朗,半沢 稔 | "Coasts, Marine Structures and Breakwaters 2013 (第10回) pp.708-717" |

| Armor Block Stability of Submerged Breakwaters Predicted by Numerical Wave Flume | 松本 朗,真野 明 (東北大),三井 順,半沢 稔 | "International Coastal Symposium 2013 (第12回)Book of Abstractsp.163" |

| Turbulence Model Effects on VOF Analysis of Breakwater Overtopping during the 2011 Great East Japan Tsunami | Jeremy D. Bricker (東北大),高木泰士 (東工大),三井 順 | International Association for Hydro-Environment Engineering and Research 2013 (第35回) |

| Numerical Analysis on Stability of Armor Blocks Covering Breakwater Rubble Mound against Tsunami Overflow | 三井 順 | International Workshop on the Application of Fluid Mechanics to Disaster Reduction |

| Bench-Scale testing and Quality Control/Quality Assurance Testing for Deep Mixing at Levee LPV 111 | Alessandro Bertero Filippo Maria,Leoni George Filz,Mitsuo Nozu,David Druss | 4th International Conference on Grouting and Deep Mixing (ICOG2012) |

| EVALUATION OF IMPROVED GROUND BY COMPACTION METHOD CONSIDERING PERFORMANCE-BASED DESIGN | Kenji Harada,Susumu Yasuda,Hiroki Kanemaru,Hironori Shitaeda,Keisuke Ishikawa | "SECOND INTERNATIONAL CONFERENCE ON PERFORMANCE-BASED DESIGN IN EARTHQUAKE GEOTECHNICAL ENGINEERING pp.731-740" |

| Dynamic VS. Static Improvement of Potentially Liquefiable Soil | Alessandro Bertero Giovanni,Pagotto Mitsuo Nozu,Paolo Zuffi | 2nd International Conference on Performance-based Design in Eathquake Geotechnical Engineering |

| Remedy of Deep Soil Mixing for Montmorillonite Clay Deposited in the Mekong and Mississippi Deltas | Mitsuo Nozu,Ngo Tuan Anh,Naotoshi Shinkawa,Kazunori Matsushita | International Symposium & Short Courses TC211 IS-GI Brussels |

| Sand Compaction Pile Technology and its Performance in both Sandy and Clayey Grounds | 木下洋樹,原田健二,野津光夫,大林淳 | "ISSMGE - TC 211 International Symposium on Ground Improvement IS-GIVol.Ⅱ,Session1,KINSAN" |

| 水硬性スラグコンパクションパイル材料 | 土田孝,森川嘉之,篠崎晴彦,木下洋樹 | "地盤工学会誌7月号 pp.28-29" |

| 固化改良と矢板を併用した基礎形式の支持特性に対する遠心模型実験 | 佐藤崇,斉藤翔,金子賢治,深田久 | "第47回地盤工学研究発表会(八戸) pp.1055-1056" |

| 地盤改良した河川堤防の地震時変形解析へのALID の適用性の検討 | 安田進,原田健二,石川敬祐,金丸功希 | "第47回地盤工学研究発表会(八戸) pp.1353-1354" |

| 河川堤防を対象とした液状化に対する地盤改良の適切な位置に関する解析 | 安田進,原田健二,金丸功希,肥後成一 | "第47回地盤工学研究発表会(八戸) pp.1355-1356" |

| 空気注入不飽和化工法の現地実証実験 その1:徳島県鳴門市での実験概要 | 岡田克寛,青木宏彦,磯谷修二,大石雅彦,高野仁,岡村未対 | "第47回地盤工学研究発表会(八戸) pp.1521-1522" |

| 空気注入不飽和化工法の現地実証実験 その2:注入間隔の検討 | 山浦昌之,浅田英幸,新川直利,藤井直,岡田克寛,岡村未対 | "第47回地盤工学研究発表会(八戸) pp.1523-1524" |

| 空気注入不飽和化工法の現地実証実験 その3:注入空気のモニタリング | 新川直利,三枝弘幸,藤井直,山田直之,岡田克寛,岡村未対 | "第47回地盤工学研究発表会(八戸) pp.1525-1526" |

| 空気注入不飽和化工法の現地実証実験 その4:事後調査 | 藤井直,浅田英幸,三好朗弘,山浦昌之,岡田克寛,岡村未対 | "第47回地盤工学研究発表会(八戸) pp.1527-1528" |

| 空気注入不飽和化工法の現地実証実験 その5:千葉県袖ヶ浦市での実験概要 | 太田正規,磯谷修二,大内正敏,高野仁,岡田克寛,岡村未対 | "第47回地盤工学研究発表会(八戸) pp.1529-1530" |

| 空気注入不飽和化工法の現地実証実験 その6:千葉県袖ヶ浦市での実験結果 | 三枝弘幸,三好朗弘,藤井直,山田直之,岡田克寛,岡村未対 | "第47回地盤工学研究発表会(八戸) pp.1531-1532" |

| 空気注入不飽和化工法を適用した場合の耐震補強工法 | 曽根照人,小泉勝彦,浅田英幸,新川直利,大石雅彦,山浦昌之,岡村未対 | "第47回地盤工学研究発表会(八戸) pp.1533-1534" |

| 仙台空港における耐震化工事の施工管理と改良効果について ~その1~ | 諸星一信,鈴木昭宏,工藤英輝,鈴木亮彦,安藤滋郎,田中隼矢 | "第47回地盤工学研究発表会(八戸) pp.1545-1546" |

| 仙台空港における耐震化工事の施工管理と改良効果について ~その2~ | 諸星一信,鈴木昭宏,工藤英輝,鈴木亮彦,安藤滋郎,田中隼矢 | "第47回地盤工学研究発表会(八戸) pp.1547-1548" |

| 液状化現象のメカニズムの定量的把握 | 塩井幸武,深田久,橋詰豊 | "第47回地盤工学研究発表会(八戸) pp.1575-1576" |

| 細粒分を含む土の間隙比の範囲について | 原田健二,石原研而 | "第47回地盤工学研究発表会(八戸) pp.335-336" |

| 高圧噴射攪拌改良土の透水試験と遮水性能について | 服部健太,日置和昭,橋本篤,村上恵洋 | "第47回地盤工学研究発表会(八戸) pp.841-842" |

| 東北地方太平洋沖地震による東京湾周辺地帯の液状化に基づく年代効果の検討 | 田口雄一,東畑郁生,青山翔吾,大坪正英 | 第47回地盤工学研究発表会(八戸) |

| 細粒分を含む砂質土の相対密度および液状化強度評価に関する検討 | 中澤博志,原田健二 | "土木学会論文集 A1(構造・地震工学)Vol.68,No.4 pp.282-292" |

| 米国ニューオリンズにおける堤防嵩上げのための深層混合処理工とモンモリロナイト系現地粘土のセメント撹拌特性 | 野津光夫,榊原優,松下和紀,中井則之 | "地盤工学会誌 9月号 pp.12-15" |

| 高圧噴射攪拌改良土の透水性能に関する考察 | 服部健太,日置和昭,橋本篤,村上恵洋 | "土木学会第67回年次学術講演会(平成24年9月) pp.119-120" |

| 細粒分を含む砂の相対密度の補正法に関する検討 | 中澤博志,原田健二 | "土木学会第67回年次学術講演会(平成24年9月) pp.1-2" |

| 細粒分を含む土の貫入抵抗値と相対密度の関係 | 原田健二,石原研而 | "土木学会第67回年次学術講演会(平成24年9月) pp.411-412" |

| 空気注入不飽和化工法の開発 その1:現地実験(徳島県鳴門市)の概要 | 岡田克寛,太田正規,磯谷修二,大内正敏,高野仁,岡村未対 | "土木学会第67回年次学術講演会(平成24年9月) pp.491-492" |

| 空気注入不飽和化工法の開発 その2:注入孔間隔設定実験 | 藤井直,三枝弘幸,三好朗弘,山田直之,岡田克寛,岡村未対 | "土木学会第67回年次学術講演会(平成24年9月) pp.493-494" |

| 空気注入不飽和化工法の開発 その3:注入口配置に関する解析検討 | 山浦昌之,浅田英幸,新川直利,藤井直,岡田克寛,岡村未対 | "土木学会第67回年次学術講演会(平成24年9月) pp.495-496" |

| 空気注入不飽和化工法の開発 その4:空気注入とそのモニタリング | 新川直利,三枝弘幸,藤井直,山田直之,岡田克寛,岡村未対 | "土木学会第67回年次学術講演会(平成24年9月) pp.497-498" |

| 空気注入不飽和化工法の開発 その5:事後調査結果 | 浅田英幸,三好朗弘,藤井直,山浦昌之,岡田克寛,岡村未対,吉田正 | "土木学会第67回年次学術講演会(平成24年9月) pp.499-500" |

| 空気注入不飽和化工法の開発 その6:千葉県袖ヶ浦市での現場実験(実験概要) | 太田正規,磯谷修二,大内正敏,高野仁,岡田克寛,岡村未対 | "土木学会第67回年次学術講演会(平成24年9月) pp.501-502" |

| 空気注入不飽和化工法の開発 その7:千葉県袖ヶ浦市での現場実験(品質確認) | 三枝弘幸,三好朗弘,藤井直,山田直之,岡田克寛,岡村未対 | "土木学会第67回年次学術講演会(平成24年9月) pp.503-504" |

| 空気注入不飽和化工法の開発 その8:設計法の概要 | 小泉勝彦,青木宏彦,磯谷修二,藤井直,山浦昌之,岡村未対 | "土木学会第67回年次学術講演会(平成24年9月) pp.505-506" |

| 空気注入不飽和化工法の開発 その9:レベル2地震動に対する照査の一例 | 曽根照人,小泉勝彦,浅田英幸,新川直利,藤井直,山浦昌之,岡村未対 | "土木学会第67回年次学術講演会(平成24年9月) pp.507-508" |

| TRD掘削機を利用した変位緩衝溝による締固め砂杭施工時の周辺変位防止対策 | 武田聡,鵜野雅明,齊藤宏彰 | "土木学会第67回年次学術講演会(平成24年9月) pp.751-752" |

| "固化杭を併用した静的締固め工法によって支持された研究施設(その5:東北地方太平洋沖地震後の基礎地盤の挙動)" | 吉富宏紀,堀井宏謙,八重樫光,西正晃 | "2012年日本建築学会学術講演大会 pp.569-570" |

| 静的締固め砂杭工法における造成時の押力測定結果 | 武田尚也,吉富宏紀 | "2012年日本建築学会学術講演大会 pp.583-584" |

| Behavior of Sandy Soils during the 2011 Gigantic Earthquake in Japan | Ikuo Towhata,Yuichi Taguchi,Toshihiko Hayashida,Tetsuya Sasaki | 第4回中央アジア地盤工学シンポジウム |

| An FEM simulation on the seismic induced deformation of SCP improved ground considering the inter-pile ground conditions. | Keisuke Kitade,Yoshinori Takahashi,Hiroki Kinoshita,Koji Ichii | 15TH WORLD CONFERENCE ON EARTHQAKE ENGINEERING |

| Characteristics of liquefaction in TokyoBay area by the 2011 Great East Japan Earthquake | Susumu Yasuda,Kenji Harada,Keisuke Ishikawa,Yoshiki Kanemaru | "Soils and Foundations Vol.52,Issue5 pp.793-810" |

| 2次元地震応答解析によるソイルセメント遮水壁の耐震性能評価 | 樋口良,村上恵洋,日置和昭 | "日本材料学会第10回地盤改良シンポジウム論文集(平成24年10月京都) pp.139-144" |

| 高圧噴射攪拌改良土の透水試験と遮水性能に関する考察 | 日置和昭,服部健太,橋本篤,村上恵洋 | "日本材料学会第10回地盤改良シンポジウム論文集(平成24年10月) pp.255-258" |

| 2011 年東北地方太平洋沖地震における締固めによる地盤改良効果の検証 | 原田健二,大林淳,田口雄一,安田進 | "第10回地盤改良シンポジウム論文集 pp.83-90" |

| 砂圧入式静的締固め工法(SAVE-SP工法)による既設構造物の液状化対策 | 深田久,竹内秀克 | "地盤工学会誌 Vol.60 No.11 pp.24-25" |

| 締固めによる改良域境界の各種仕様ごとの地震時変形挙動の相違について | 田口雄一,大林淳,原田健二,今井優輝 | "日本地震工学会大会2012 pp.274-275" |

| 細粒分を含む土の最小間隙比と相対密度についての一考察 | 原田健二,石原研而 | "日本地震工学会大会2012 pp.276-277" |

| EXPERIMENTAL STUDY ON SUBSIDENCE OF SURFACE STRUCTURES DUE TO LIQUEFACTION AND ITS MITIGATION | Rouzbeh Rasouli,Toshihiko Hayashida,Ikuo Towhata | 第1回日本地震工学国際シンポジウム |

| Damage in and around River Levees Caused by the 2011 Northeast and Pacific Ocean Earthquake | Yasushi Sasaki,Ikuo Towhata,Kenya Miyamoto,Masami Shirato,Akiyoshi Narita,Tetsuya Sasaki,Shunsuke Sako,Yuichi Taguchi | the special issue of Soils and Foundation Journal on the earthquake in 2011 |

| Liquefaction consequences and learned lessons during the 2011 M=9 gigantic earthquake | Ikuo Towhata,Shigeru Goto,Yuichi Taguchi,Shogo Aoyama | Proceedings of Indian Geotechnical Conference |

| 盛土施工における締固め特性について(その1)-大型締固め機械の締固め特性について- | 西山章彦,茂木正晴,黒台昌弘,小林純,高橋浩 | 土木学会第67回年次学術講演会 |

| 盛土施工における締固め特性について(その2)-加速度応答法の適用範囲の検討- | 砂町康夫,内山恵一,藤野健一,山口達也,木村誠,高橋浩,小林純 | 土木学会第67回年次学術講演会 |

| 超軟弱で高被圧な地盤に回転鋼管杭で挑戦-伊豆縦貫大場南高架橋下部工事- | 山中 健大 | "土木施工 2012年7月号 P90" |

| "流れ分析法による土壌中の全シアン及び チオシアン酸イオンの同時定量" | 野口 和宏,福永 和久,今安 英一郎,埜村 朋之,山下 信彦,萩野 芳章,野々村 誠,細見 正明 | "分析化学(日本分析化学会) Vol.61(2012)No.12 pp1079-1084" |

| 土壌還元法による揮発性有機化合物汚染地下水・土壌の浄化技術 | 萩野 芳章 | "土木施工 2012年8月号 pp55~56" |

| 数値解析に基づく人工リーフ被覆ブロックの安定性の評価手法 | 松本 朗,真野 明 (東北大),三井 順,半沢 稔 | "土木学会論文集B2 (海岸工学) Vol.68,No.2pp.861-865" |

| 防波堤を越流する津波に対する港内側マウンド被覆材の安定性に関する研究 | 三井 順,丸山草平,松本 朗,半沢 稔 | "土木学会論文集B2 (海岸工学) Vol.68,No.2pp.881-885" |

| 防波堤港内側マウンド被覆材の津波に対する安定性に関する実験 | 丸山草平,松本 朗,半沢 稔 | "土木学会論文集B3 (海洋開発) Vol.68,No.2pp.7-12" |

| 消波ブロックの形状特性と景観(調和感)に関する多角的評価項目の検討 | 袖山和志,櫻木義己,萩原照通,柴田あずさ | "土木学会論文集B3 (海洋開発) Vol.68,No.2pp.546-551" |

| 没水型長周期波対策工の消波特性に関する実験的検討 | 田中真史,松本 朗,半沢 稔 | "土木学会論文集B3 (海洋開発) Vol.68,No.2pp.816-821" |

| 人工リーフにおける有孔型被覆ブロックの水理特性と安定性に関する実験的研究 | 黒岩正光・松原雄平 (鳥取大),前田祝幸 (中国地整),木下勝尊,木島克己 | "土木学会年次学術講演会講演概要集 (第67巻)Ⅱ-242号,pp.483-484" |

| 天端が静水面に位置する混成堤背面マウンド構造物の越波に対する安定実験 | 田中真史,松本 朗,半沢 稔 | "土木学会年次学術講演会講演概要集 (第67巻)Ⅱ-243号,pp.485-486" |

| 廃コンクリートの低環境負荷完全リサイクルに関する研究 | 河村景史・堺 孝司 (香川大),錦織和紀郎,北垣亮馬 (東京大) | "コンクリート工学年次論文集 (第34巻1号)pp.1492-1497" |

| 海岸構造物の建設によるCO2排出と供用後の藻場形成に伴うCO2固定に基づく環境負荷低減効果の評価 | 錦織和紀郎,伊藤 靖 (漁港漁場漁村技術研究所),堺 孝司 (香川大),柴田早苗,廣瀬紀一 | "水産工学 (第49巻第2号)pp.113-123" |

| Stability of Wave-dissipating Concrete Blocks of Detached Breakwaters against Tsunami | 半沢 稔,松本 朗,田中 仁 (東北大) | ICCE 2012 (国際海岸工学会議 (第33回) ) |

| Stability Prediction on Armor Blocks for Submerged Breakwater by Computational Fluid Dynamics | 松本 朗,真野 明 (東北大),三井 順,半沢 稔 | ICCE 2012 (国際海岸工学会議 (第33回) ) |

| Behabior of Fish Reef Blocks Falling through Water | 三井 順,緒方信一,柴田早苗,松本 朗,山本方人 (三柱) | ICCE 2012 (国際海岸工学会議 (第33回) ) |

| Detached Breakwaters' Stability against Solitary Tsunami Wave | 半沢 稔,松本 朗,田中 仁 (東北大) | "the 4th International Conference on Estuaries and Coastspp.321-327" |

| Effects of Water Depth on Stability of Armor Block for Composite Breakwaters | 松本 朗,半沢 稔,真野 明 (東北大) | "the 4th International Conference on Estuaries and Coastspp.328-336" |

| Applicability of CADMAS-SURF to Evaluate Detached Breakwater Effects on Solitary Tsunami Wave Reduction | 半沢 稔,松本 朗,田中 仁 (東北大) | "Earth Planets Space Vol.64 (No.10)pp.955-964" |

| Punching Failure of Kamaishi Breakwater Caisson Foundations during The 2011 Great East Japan Tsunami | Jeremy D. Bricker (東北大),高木泰士 (東工大),三井 順 | "the 10th International Conference on Urban Earthquake Engineeringpp.1875-1882" |

| Complete Recycling of Demolished Concrete with Low Environmental Loads | 錦織和紀郎,堺 孝司 (香川大) | "the 9th fib International PhD Symposium in Civil Engineeringpp.411-418" |

| 地盤改良工事(CI-CMC工法)における施工管理の創意工夫 | 岡戸雅則,川村幸一,増田圭吾,関友亮 | "地盤工学会誌 Vol.59,No.6 pp.16-19" |

| 都市を襲った液状化① 地盤改良が明暗を分かつ | 吉富宏紀 | "建築知識6月号 No.679 pp.23-24" |

| 東京湾岸における液状化被害 | 安田進,原田健二 | "地盤工学会誌 Vol.59,No.7 pp.38-41" |

| 固化改良と矢板を用いた基礎型式の水平抵抗特性に対する遠心模型実験 | 出町真一,佐藤崇,金子賢治,深田久 | "第46回地盤工学研究発表会 pp.1171-1172" |

| 固結特性を有する鉄鋼スラグを用いたSCP 改良地盤の地震時変形挙動(その2:再現解析による検証) | 木下洋樹,森川嘉之,高橋英紀,一井康二,篠崎晴彦 | "第46回地盤工学研究発表会 pp.1527-1528" |

| 固結特性を有する鉄鋼スラグを用いたSCP 改良地盤の地震時変形挙動(その 1:遠心模型実験) | 篠崎晴彦,森川嘉之,高橋英紀,木下洋樹,丸山憲治 | "第46回地盤工学研究発表会 pp.1529-1530" |

| 曲線トンネルの地震時変形挙動に関する振動模型実験 | 三城徹也,Ali Derakshani,東畑郁生 | "第46回地盤工学研究発表会 pp.1573-1574" |

| 盛土を対象とした締固め工法による改良位置に関する液状化解析 | 原田健二,安田進,金丸功希 | "第46回地盤工学研究発表会 pp.1773-1774" |

| 盛土を対象とした締固め工法による改良位置に関する振動台実験 | 安田進,原田健二,金丸功希,木村圭祐 | "第46回地盤工学研究発表会 pp.1775-1776" |

| 地中連続壁工法を利用した変位緩衝溝による静的締固め砂杭工法施工時の周辺に防止対策 | 大口勝義,鵜野雅明,西村佳高 | "第46回地盤工学研究発表会 pp.883-884" |

| 砂圧入式静的締固め工による周辺影響把握のための3 次元解析 | 竹内秀克,河村精一,野田利弘 | "第46回地盤工学研究発表会 pp.885-886" |

| 砂圧入式静的締固め工法の開発と現地における適用 | 後藤文男,水野健太,末岡裕司,山田哲也,深田久 | "第46回地盤工学研究発表会 pp.889-890" |

| エジェクター吐出方式による海上深層混合改良の施工 | 野澤良一,尾形太,木俣陽一,有薗芳久 | "第46回地盤工学研究発表会 pp.891-892" |

| エジェクター吐出方式による海上深層混合改良の品質 | 野澤良一,木俣陽一,鵜口正信,尾形太 | "第46回地盤工学研究発表会 pp.893-894" |

| 海外の河口域堆積粘性土地盤におけるセメント混合時の強度発現特性 | 野津光夫,中井則之 | "第46回地盤工学研究発表会 pp.899-900" |

| 静的締固め工法の動的挙動と改良効果(その1:設計概要) | 流鏑馬久明,井上啓,武田尚也,大西智晴 | "2011年度建築学会大会(関東) pp.565-566" |

| 静的締固め工法の動的挙動と改良効果(その2:改良効果の確認) | 武田尚也,大西智晴,流鏑馬久明,依田博基 | "2011年度建築学会大会(関東) pp.567-568" |

| 締固め工法による液状化対策とその効果 -東北地方太平洋沖地震における対策効果- | 吉富宏紀 | "「structure Journal of Japan Structural Consultants Association」10月号 pp.24-25" |

| Application Examples of Deep Mixing Method as Aseismic Measures | Hiroki Kinoshita,Ngo Anh Tuan,Naotoshi Shinkawa,Hisashi Fukada | The INTERNATIONAL CONFERENCE on GEOTECHNICS FOR SUSTAINABLE DEVELOPMENT(Geotec Hanoi 2011 Conference Scientific Committee) |

| 土木構造物・宅造地の液状化被害と課題 | 東畑郁生,田口雄一,青山翔吾,大坪正英 | "日本地震工学会誌 東日本大震災特集号 pp.37-40" |

| LIQUEFACTION-PROOFING THROUGH SAND COMPACTION PILE METHOD: CASE STUDIES FROM RECENT GIGANTIC EARTHQUAKES IN JAPAN | Kenji Harada,Mitsuo Nozu,Rolando Orense | 7th APRU Research Symposium on Multi-hazards around the Pacific Rim Auckland, New Zealand |

| LIQUEFACTION CONSEQUENCES AND LEARNED LESSONS DURING THE 2011 M=9 GIGANTIC EARTHQUAKE | Ikuo Towhata,Shigeru Goto,Yuichi Taguchi,Shogo Aoyama | Proceedings of Indian Geotechnical Conference |

| Bench-Scale Testing and Quality ControlQuality Assurance Testing for Deep Mixing at Levee LPV 111 | Alessandro Bertero,Filippo Maria Leoni,George Filz,Mitsuo Nozu,David Druss | 4th International Conference on Grouting and Deep Mixing |

| 東北地方太平洋沖地震による千葉県の被害 | 安田進,原田健二,石川敬祐 | "地盤工学ジャーナル Vol.7,No.1 pp.103-115" |

| 鉄鋼スラグを用いたSCP改良による重力式ケーソン構造物の基礎地盤の地震時変形特性とその評価 | 木下洋樹,一井康二,森川嘉之,高橋英紀,篠崎晴彦,高橋裕徳 | "地盤工学ジャーナル Vol.7,No.1 pp.323-337" |

| 土壌中の全シアン分析を目的とした塩化第二銅及び塩化第一スズを用いる還元蒸留法の検討 | 野口和弘,福永和久,山下信彦,萩野芳章,野々村誠 | "分析化学(日本分析化学会) Vol.61(2012)No.1 pp31~36" |

| 土壌中の全シアン含有量分析手法の検討 | 野口和弘,福永和久,山下信彦,萩野芳章,野々村誠 | "日本工業用水協会研究発表会講演要旨 2012 47th pp82~85" |

| 離岸堤消波ブロックの津波に対する安定性に関する実験的研究 | 半沢 稔,松本 朗,田中 仁 (東北大),山本方人 | "土木学会論文集B2 (海岸工学) Vol.67,No.2pp.796-800" |

| 魚礁ブロックの水中落下挙動に関する研究 | 三井 順,緒方信一,柴田早苗,山本方人 | "土木学会論文集B2 (海岸工学) Vol.67,No.2pp.806-810" |

| 人工リーフ被覆ブロックの初期移動の予測手法 | 松本 朗,真野 明 (東北大),半沢 稔,山本方人 | "土木学会論文集B2 (海岸工学) Vol.67,No.2pp.816-820" |

| コンクリートブロックを用いた海岸・港湾構造物の環境性能評価 | 錦織和紀郎,堺 孝司 (香川大),瀧本聖吾,昇 悟志 | "土木学会論文集B2 (海岸工学) Vol.67,No.2pp.1221-1225" |

| 消波ブロックの形状特性と景観(調和感)の関係についての検討 | 袖山和志,松浦繁徳,木島克己,山本宏樹,柴田あずさ | "土木学会論文集B3 (海洋開発) Vol.67,No.2pp.808-813" |

| 長崎県壱岐市大島における磯焼け対策技術の検証-第2報 植食性魚類の食害対策としての防御材の効果 | 柴田早苗,青田 徹,山仲洋紀 (壱岐栽培センター),山本方人,我原弘昭 | "平成23年度日本水産工学会学術講演会論文集pp.91-94" |

| 和歌山県雑賀崎漁港における藻場造成 | 廣瀬紀一,青田 徹 | "海環境と生物および沿岸環境修復技術に関するシンポジウム発表論文集 (第10回)pp.61-66" |

| 長崎県壱岐市大島漁港における磯焼け対策 | 柴田早苗,青田 徹,山仲洋紀 (壱岐栽培センター),山本方人,我原弘昭 | "海環境と生物および沿岸環境修復技術に関するシンポジウム発表論文集 (第10回)pp.113-118" |

| 波浪に対する抜群の安定性「ペルメックス」 | 錦織和紀郎 | "北陸の建設技術 (2011年8月号)pp.11-14" |

| Development of A Nursery Block for Snow Crabs Ensuring Stable Behavior during Free Drop in Water | 緒方信一,山本方人,柴田早苗,三井 順 | "Coastal Structures 2011 (第6回)pp.755-766" |

| Evaluation of the Critical Condition on Armor Block Stability for Submerged Breakwaters | 松本 朗,山本方人,真野 明 (東北大) | "Coastal Structures 2011 (第6回)pp.834-845" |

| Experimental Research on Detached Breakwaters' Effect on Tsunami Disaster Mitigation | 半沢 稔,松本 朗,田中 仁 (東北大) | "Coastal Structures 2011 (第6回)pp.1276-1286" |

| "A Light Concrete Block Stabilized by Distributed Holes for SubmergedBreakwaters" | 松本 朗,山本方人,真野 明 (東北大) | "Journal of Coastal Research, Special Issue 64pp.567-571" |

| Three-Dimensional Numerical Analysis of Jet-Induced Local Scouring in Front of Quay Walls and Its Countermeasure Using Filter Units | 中村友昭・水谷法美 (名古屋大),篠田陽介 (JFEエンジニアリング),小山裕文 | "Coastal Engineering Journal Vol.53,No.1pp.41-62" |

| Lateral Stress Effects on Liquefaction Resistance Correlations | Kenji Harada, Roland P. Orense, Kenji Ishihara, Jun Mukai | "New Zealand Society for Earthquake Engineering Bulletin, Vol. 43, No.1 pp.13-23" |

| Numerical analysis on co- and postseismic behavior of sandy/clayey soil ground improved by sand compaction pile method | Hidekatsu Takeuchi, Toshihiro Noda, Akira Asaoka | "SOIL DYNAMICS AND EARTHQUAKE ENGINEERING, Proc. of Sessions of GeoShanghai2010, Shanghai, China, ASCE pp.218-224" |

| 3次元解析を用いた砂圧入式静的締固めの周辺構造物に及ぼす影響検討 | 河村精一, 竹内秀克, 野田利弘, 浅岡 顕 | "第22回中部地盤工学シンポジウム pp.115-120" |

| 性能設計を考慮した締固めによる改良仕様の設定に関する研究(その3) | 安田 進,下枝浩徳,,大林 淳, 原田健二, 新川直利 | "第45回地盤工学研究発表会(松山) pp.1079-1080" |

| 固化改良と矢板を併用した基礎構造物の水平抵抗に対する遠心載荷模型実験 | 近 裕太,金子賢治,深田 久 | "第45回地盤工学研究発表会(松山) pp.1097-1098" |

| 液状化対策としての格子状深層混合処理工法の改良深さ低減に関する遠心模型実験 | 高橋英紀,森川嘉之,深田 久,田口博文,徳永幸彦,丸山憲治 | "第45回地盤工学研究発表会(松山) pp.1427-1428" |

| 浮き型格子状深層混合処理工法の液状化地盤への適用性に関する遠心模型実験 | 高橋英紀,森川嘉之,深田 久,田口博文,徳永幸彦,竹花和浩 | "第45回地盤工学研究発表会(松山) pp.1429-1430" |

| SCP改良砂地盤の塑性膨張を伴う硬化による耐震メカニズム | 竹内秀克,野田利弘,浅岡 顕 | "第45回地盤工学研究発表会(松山) pp.1549-1550" |

| 海外の河口域堆積粘性土における室内配合試験時の強度発現特性 | 野津光夫,中井則之 | "第45回地盤工学研究発表会(松山) pp.583-584" |

| 固結特性を有する鉄鋼スラグを用いたSCP改良地盤の遠心模型実験 | 高橋英紀,森川嘉之,篠崎晴彦,新川直利,丸山憲治 | "第45回地盤工学研究発表会(松山) pp.789-790" |

| 砂圧入式静的締固め工法(SAVE-SP工法)の改良効果に関する一考察 | 伊藤竹史,大林淳,福島信吾,磯谷修二,野田洋 | "第45回地盤工学研究発表会(松山) pp.803-804" |

| 砂圧入式静的締固め工法(SAVE-SP工法)の使用材料に関する一考察 | 磯谷修二,大林 淳,野田 洋,渡辺英次,福島信吾,櫛原信二 | "第45回地盤工学研究発表会(松山) pp.805-806" |

| 鉄鋼スラグを用いたSCP改良地盤の変形特性 | 高橋裕徳,一井康二,植村一瑛,仁科晴貴,篠崎晴彦,木下洋樹 | "第45回地盤工学研究発表会(松山) pp.477-478" |

| 暴露状態の気泡混合軽量土の長期性状について | 山田智史, 高木宗男, 横田聖哉, 佐藤嘉広, 橋本則之, 後藤年芳 | "第45回地盤工学研究発表会(松山) pp.619-620" |

| 部分的に固化改良したゆるい砂地盤の地震時/地震後応答解析 | 竹内秀克, 中井健太郎, 野田利弘 | "応用力学論文集,土木学会,Vol.13,pp.1-8 pp.443-452" |

| 大径単軸変位低減型深層混合処理工法(CDM-LODIC)の現場実証実験 | 上村一義,佐藤秀幸,上 周史,深田 久 | "土木学会第65回年次学術講演会 pp.1003-1004 (Ⅲ-501)" |

| 熊本・宇土道路における側方流動対策としてのコラムリンク工法の試験施工 | 新川直利,堤 祥一,川原 実,川崎廣貴 | "土木学会第65回年次学術講演会 pp.1005-1006 (Ⅲ-503)" |

| 杭と地盤改良を併用する複合地盤基礎の実大規模実験(その3:再固化) | 深田 久,冨澤 幸一,木村 亮 | "土木学会第65回年次学術講演会 pp.655-656 (Ⅲ-328)" |

| 細粒分を含む砂の相対密度と液状化強度に関する検討 | 中澤博志,原田健二 | "土木学会第65回年次学術講演会 pp.685-686 (Ⅲ-343)" |

| 水平応力が液状化強度に及ぼす影響についての一考察 | 原田健二,石原研而,Roland P. Orense | "土木学会第65回年次学術講演会 pp.999-1000 (Ⅲ-500)" |

| 固化杭を併用した静的締固め工法によって支持された研究施設(その3:計測概要) | 八重樫 光,堀井 宏謙,西 正晃,大西 智晴,吉富 宏紀 | "日本建築学会大会学術講演概要集(北陸)2010年9月 pp.457-458" |

| 固化杭を併用した静的締固め工法によって支持された研究施設(その4:計測結果の考察) | 八重樫 光,堀井 宏謙,西 正晃,大西 智晴,吉富 宏紀 | "日本建築学会大会学術講演概要集(北陸)2010年9月 pp.459-460" |

| 弾性波速度から求めた地盤のポアソン比の検討 | 田部井 哲夫,牛山 祐紀,畑中 宗憲,大西 智晴,田地 陽一 | "日本建築学会大会学術講演概要集(北陸)2010年9月 pp.477-478" |

| 地盤改良工法の環境面における動向・課題と今後の展望 | 大西 智晴 | "日本建築学会大会学術講演概要集(北陸)2010年9月 pp.48-58" |

| 密度増大工法により改良された地盤の静止土圧係数に与える細粒分含有率の影響 | 田部井 哲夫,畑中 宗憲,大西 智晴,田地 陽一 | "日本建築学会大会学術講演概要集(北陸) 2010年9月 pp.495-496" |

| 砂圧入式静的締固め工法(SAVE-SP工法)の開発と適用事例 | 福島信吾,野田 洋,櫛原信二,木下洋樹 | "材料学会,第9回地盤改良シンポジウム論文集 pp.243-248" |

| A comparative study on influence of soft clay properties for deep soil cement mixing in the deltas of Mekong and Mississippi | Mitsuo Nozu, Noriyuki Nakai | "Proc. of the International Symposium HANOI GEOENGINEERING 2010 pp.59-64" |

| Case history Deep mixing for the New Orleans east back levee (USA) | Wesley Schmutzler, Mitsuo Nozu, Masaru Sakakibara, Alessandro Bertero | "ISSMGE Bulletin, Volume 5, Issue 1 pp.5-14" |

| 固結特性を有する鉄鋼スラグを用いたSCP改良地盤の地震時変形挙動の評価 | 木下洋樹,一井康二,土田孝,森川嘉之,高橋英紀,篠崎晴彦,丸山憲治,高橋裕徳 | "広島大学大学院工学研究科研究報告, Vol.59,no.1(2010)" |

| 固結特性を有する鉄鋼スラグを用いたSCP改良地盤の埋立載荷荷重に対する安定性 | 高橋英紀,森川嘉之,篠崎晴彦,木下洋樹,丸山憲治 | "地盤工学ジャーナル Vol.6(2011),No.1 pp.81-95" |

| 消波工の変形過程が波力低減効果の変化に及ぼす影響 | 久保田真一,山本方人,松本 朗,半沢 稔,荒木進歩・出口一郎 (大阪大) | "土木学会論文集B2 (海岸工学)Vol.66,No.1pp.866-870" |

| 離岸堤の津波防災効果に関する実験的研究 | 半沢 稔,松本 朗,田中 仁 (東北大),山本方人 | "土木学会論文集B2 (海岸工学)Vol.66,No.1pp.886-890" |

| 防波堤を支持する海底地盤の異方的力学特性と簡易支持力評価 | 瀧本聖吾,三浦清一 (北海道大),川村志麻 (室蘭工大),横浜勝司 (北海道大) | "土木学会論文集B2 (海岸工学)Vol.66,No.1pp.906-910" |

| コンクリートブロックを用いた海岸・港湾構造物の環境性能評価 | 半沢 稔,松本 朗,田中 仁 (東北大) | "応用力学論文集 (第13巻)pp.797-804" |

| 離岸堤消波ブロックの津波に対する安定性について | 半沢 稔,松本 朗,田中 仁 (東北大) | "東北地域災害科学研究 (第47巻)pp.101-106" |

| 長崎県壱岐市大島における磯焼け対策技術の検証 | 柴田早苗,青田 徹,山仲洋紀 (壱岐栽培センター),山本方人 | "平成22年度日本水産工学会学術講演会論文集pp.61-64" |

| Restoration of Kelp Beds on an Urchin Barren : Removal of Sea Urchins by Citizen Divers in Southwestern Hokkaido | 綿貫 啓 (アルファ水工),青田 徹,大塚英治 (沿海調査エンジニアリング),川井唯史 (稚内水産試験場),岩橋好敏 (全国豊かな海づくり推進協会),桑原久実 (水産工学研究所),藤田大介 (東京海洋大) | "水産総合研究センター研究報告第32号pp.83-87" |

| Impact Force Analysis on Wave Dissipating Concrete Blocks during Rocking Motion | 三井 順,山本方人,昇 悟史,西脇一郎 | ICCE 2010 (国際海岸工学会議 (第32回) ) |

| Applicability of CADMAS-SURF to Detached Breakwater Effects on Solitary Tsunami Wave Reduction | 半沢 稔,松本 朗,田中 仁 (東北大) | International Tsunami Field Symposium (第3回) |

| Environmental Effects of A New Concrete Armor Block | 錦織和紀郎,堺 孝司 (香川大),瀧本聖吾,昇 悟志 | "International Conference on Concrete under Severe Conditions (第6回)pp.1613-1620" |

| SOFT SOIL TREATMENT WITH WET MIXING SOIL CEMENT COLUMN OF JAPANESE TECHNOLOGY IN MEKOUNG RIVER DELTA | Nguyen Bach Tung, Pham Ngoc Hung, Mitsuo Nozu, Jun Mukai | "Deep Mixing 2009 Okinawa Symposium pp.279-282" |

| APPLICATION EXAMPLES OF DEEP MIXING METHOD AS ASEISMIC MEASURES | Naotoshi Shinkawa, Michio Bessho | "Deep Mixing 2009 Okinawa Symposium pp.365-368" |

| LONG-TERM STRENGTH OF COLUMNS WITH DJM METHOD | Naotoshi Shinkawa, Mitsuo Nozu, Masahiro Inagaki | "Deep Mixing 2009 Okinawa Symposium pp.445-448" |

| APPLICATION EXAMPLE OF DEEP MIXING METHOD WITH REDUCED DISPLACEMENT DUE TO MIXING (CDM-LODIC) | Kazuyoshi Kamimura, Chikashi Kami, Toshiro Hara, Tatsuo Takahashi, Hisashi Fukada | "Deep Mixing 2009 Okinawa Symposium pp.535-540" |

| DEVELOPMENT OF TRIPLE-AXIAL CEMENT DEEP MIXING METHOD (LEMNI 2/3 METHOD) | Kazuyoshi Kamimura, Hirotaka Kawasaki, Toshiro Hara, Tatsuo Takahashi, Hisashi Fukada | "Deep Mixing 2009 Okinawa Symposium pp.541-546" |

| COSEISMIC AND POSTSEISMIC BEHAVIOR OF INTERMEDIATE SOIL GROUND IMPROVED BY SAND COMPACTION PILE METHOD | Hidekatsu Takeuchi, Toshihiro Noda, Akira Asaoka | "International Conference on Performance-Based Design in Earthquake Geotechnical Engineering ? from case history to practice ? (IS-Tokyo) pp.1199-1205" |

| 不燃性廃棄物と焼却灰および一般土質材料を組み合わせた複合地盤におけるクリープ特性に関する実験的研究 | 久保陽太郎,江副哲,東畑郁生 | "第8回環境地盤工学シンポジウム pp.351-358" |

| 表面波探査による仙台空港の液状化層分布把握 | 青池邦夫,大友正悦,鈴木亮彦,村上弘行,比留間誠之 | "第44 回地盤工学研究発表会(横浜) pp.135-136" |

| 流動化砂の圧入による地盤の締固め工法(その1:工法の概要) | 東祥二,深田久,櫛原信二,今井優輝 | "第44回地盤工学研究発表会(横浜) pp.749-750" |

| 流動化砂の圧入による地盤の締固め工法(その2:試験施工と改良効果) | 磯谷修二,仁田尾洋,櫛原信二,今井優輝 | "第44回地盤工学研究発表会(横浜) pp.751-752" |

| 矢板と固化改良を併用した基礎構造物に対する遠心水平載荷模型実験 | 西村郷,鈴木崇也,金子賢治,深田久 | "第44 回地盤工学研究発表会(横浜) pp.1255-1256" |

| 改良体を有する砂質地盤~盛土系の地震中・地震後変形挙動の3 次元水~土連成解析 | 高稲敏浩,浅岡顕,野田利弘,竹内秀克 | "第44回地盤工学研究発表会(横浜) pp.1413-1414" |

| SCP改良された砂地盤と粘土地盤の地震中・地震後挙動の比較 | 竹内秀克,浅岡顕,野田利弘 | "第44回地盤工学研究発表会(横浜) pp.1609-1610" |

| 不燃性廃棄物と一般土質材料の複合地盤におけるクリープ特性に関する実験的研究 | 久保陽太郎,東畑郁生 | "第44回地盤工学研究発表会(横浜) pp.1931-1932" |

| 地盤改良工法における地盤定数の評価 | 大西智晴 | "日本建築学会大会 パネルディスカッション資料 基礎構造設計における地盤定数の評価の役割と課題 pp.43-50" |

| "固化杭を併用した静的締固め工法によって支持された研究施設 その1:設計概要" | 八重樫光,堀井宏謙,大西智晴,吉富宏紀,海上仁 | "日本建築学会大会学術講演梗概集(東北) pp.487-488" |

| "固化杭を併用した静的締固め工法によって支持された研究施設 その2:施工管理および品質管理結果" | 吉富宏紀,大西智晴,堀井宏謙,西正晃,山崎勉 | "日本建築学会大会学術講演梗概集(東北) pp.489-490" |

| 圧縮性間隙水を有する砂地盤の地震時液状化/締固め挙動の計算 | 竹内秀克,野田利弘,浅岡顕 | "応用力学論文集Vol.12 pp.321-330" |

| 3次元動的/静的水~土連成解析による砂質地盤に設置されたリング状改良壁の改良効果の検討 | 高稲敏浩,浅岡顕,野田利弘,竹内秀克 | "土木学会第64回年次学術講演会 pp.513-514(Ⅲ-257)" |

| 地震動の違いによるSCP改良砂地盤・粘土地盤の地震中・地震後挙動の比較 | 竹内秀克,浅岡顕,野田利弘 | "土木学会第64回年次学術講演会 pp.539-540(Ⅲ-270)" |

| 固化改良と鋼矢板併用による複合型直接基礎の水平・鉛直抵抗特性 | 深田久,磯部公一,木村亮 | "土木学会第64回年次学術講演会 pp.727-728(Ⅲ-364)" |

| 既設護岸に対する砂圧入式静的締固め工法の適用事例(試験施工報告その1) | 東祥二,福島信吾,伊藤竹史,今井優輝,永石雅大 | "土木学会第64回年次学術講演会 pp.993-994 (Ⅲ-497)" |

| 仙台空港の誘導路における液状化対策について | 大友正悦,齊藤聡洋,久野了史,諏訪朝夫,鈴木亮彦,青池邦夫 | "土木学会第64回年次学術講演会 pp.255-256 (Ⅵ-128)" |

| Co-seismic and post-seismic behavior of an alternately layered sand-clay ground and embankment system accompanied by soil disturbance | Toshihiro Noda, Hidekatsu Takeuchi, Kentaro Nakai, Akira Asaoka | "Soils and Foundations, Vol.49, No.5 pp.739-756" |

| アーチ効果を利用した低改良率セメントコラム工法ALiCCの適用事例 | 阪上最一,新川直利 | "第28回日本道路会議 CD (33P03)" |

| 性能設計を考慮した締固めによる改良仕様の設定に関する研究(その2) | 原田健二,安田進,下枝浩徳,大林淳,新川直利 | "日本地震工学会・大会-2009梗概集 pp.238-239" |

| 砂圧入式静的締固め工法(SAVE-SP工法)の改良効果と適用事例 | 今井優輝,大林淳,福島信吾,伊藤竹史 | "第54回地盤工学シンポジウム pp.579-584" |

| 実大実験における格子状固化改良の液状化対策効果に関する研究 | 東祥二,原田健二,仁田尾洋,橋本則之,鈴木亮彦,初山幸治,舘下和行,菅野高弘,中澤博志 | "材料,第59巻,第1号 pp.14-19" |

| 軟弱地盤対策工法の最近10年の動向 | 深田久 | "地盤工学会誌,Vol.58,No.1 pp.30-31" |

| 繰返し荷重場にある構造異方性砂地盤の支持力評価法 | 瀧本聖吾,岩田雄太郎,三浦清一,川村志麻,横浜勝司 | "第44回地盤工学研究発表会 pp.821-822" |

| ハイブリッド振動遮断壁による地盤環境振動対策 | 櫛原信二 | "第52回電力土木講習会 pp.83-92" |

| 西尾市井桁川河川環境整備における底質浄化について | 古嶋忠良, 桑原正彦 | "ヘドロ No.105, pp.28-34." |

| 岸壁に作用する局所流による三次元洗堀予測手法の開発と対策工に関する研究 | 中村友昭・水谷法美・篠田陽介 (名古屋大),小山裕文 | "海岸工学論文集 (第56巻)pp.486-490" |

| 数値波動水路による越波伝達波の計算 | 松本 朗 | "海岸工学論文集 (第56巻)pp.781-785" |

| 消波ブロック被覆堤における消波工の変形過程に関する実験的検討 | 久保田真一,山本方人,松本 朗,半沢 稔 | "海岸工学論文集 (第56巻)pp.906-910" |

| 離岸堤の津波防災効果検討におけるCADMAS-SURFの適用について | 半沢 稔,松本 朗,田中 仁 (東北大) | "東北地域災害科学研究 (第46巻)pp.113-118" |

| 海洋構造物用の新型被覆ブロックの構造設計と環境性能の評価 | 瀧本聖吾,堺 孝司 (香川大),錦織和紀郎,昇 悟志 | "コンクリート工学年次論文集 (第31巻)pp.1585-1590" |

| 海岸・港湾構造物用の新しい被覆ブロックの開発と環境性能 | 錦織和紀郎,堺 孝司 (香川大),瀧本聖吾,昇 悟志 | "土木建設技術発表会2009pp.257-264" |

| 「有性生殖によるサンゴ増殖の手引き」について | 中村 誠・森 健二 (水産庁漁港漁場整備部),中村良太・安藤 亘・石岡 昇 (水産土木建設技術センター),山本秀一・北野倫生 (エコー),綿貫 啓 (アルファ水工),青田 徹,三上信雄 (水産工学研究所) | "日本サンゴ礁学会大会講演要旨集 (第12回)p.150" |

| A Rational Design of Armor Block and Foot-Protection Block Covering Rubble Mound of Composite Breakwater | 久保田真一,下迫健一郎 (港空研),浜口正志,松本 朗,半沢 稔,山本方人 | "ISOPE 2009 (国際海洋極地工学会議 (第19回) )pp.1145-1152" |

| Local Scour in Front of Quay Wall Cased by Bow Thruster and Its Contermeasure Using Filter Units | 水谷法美・中村友昭・篠田陽介 (名古屋大),小山裕文 | "ISOPE 2009 (国際海洋極地工学会議(第19回) )pp.1280-1286" |

| Numerical Analysis on Wave Transmission over Breakwaters | 松本 朗 | "the 3rd International Conference on Estuaries and Coastspp.683-690" |

| Mechanical Behavior of Anisotropic Sand Ground Bearing Capacity Coastal Structure and Its Evaluation | 瀧本聖吾,三浦清一 (北海道大),川村志麻 (室蘭工大),横浜勝司 (北海道大) | "IS-Kyotopp.17-23" |

| EFFECT OF LATERAL STRESS ON RELATIONS BETWEEN PENETRATION RESISTANCES AND CYCLIC STRENGTH TO LIQUEFACTION | Kenji ISHIHARA,Kenji HARADA | "the 3rd International Conference on Site Characterization (Taipei) CD" |

| 間隙水の圧縮性を考慮した砂質地盤の地震時液状化/締固め挙動の計算 | 竹内秀克,野田利弘 | "計算工学講演会論文集 Vol.13 CD" |

| RELATIONS BETWEEN PENETRATION RESISTANCE AND CYCLIC STRENGTH TO LIQUEFACTION AS AFFECTED BY KC-CONDITIONS | Kenji HARADA,Kenji ISHIHARA,Rolando P. ORENSE,Jun MUKAI | "the 4th decennial Geotechnical Earthquake Engineering and Soil Dynamics Conference (GEESD) CD" |

| 砂の貫入抵抗値と相対密度の関係 | 原田 健二,石原 研而,Roland P. Orense,向井 淳 | "第43回地盤工学研究発表会(広島) pp.181-182" |

| "流動化処理土の長期強度特性 - 5 年経過時の流動化処理土の特性 -" | 大西智晴,野津光夫,藤井衛,渡辺一弘,木村匡 | "第43回地盤工学研究発表会(広島) pp.647-648" |

| "締固め固化杭に関する施工試験 -その1:試験概要および載荷試験結果-" | "伊勢本昇昭,武内義夫,沼上清,大西智晴,根本恒,山崎勉,三上博,藤原達夫" | "第43回地盤工学研究発表会(広島) pp.941-942" |

| "締固め固化杭に関する施工試験 -その3:固化杭の出来形および締固め効果-" | 吉富宏紀,金子治,西正晃,新井寿昭,市川覚,平田裕一,佐野大作 | "第43回地盤工学研究発表会(広島) pp.945-946" |

| 固化改良と矢板を併用した基礎構造物の水平抵抗に対する基礎的実験 | 松村秀俊,金子賢治,深田久,塩井幸武 | "第43回地盤工学研究発表会(広島) pp.1335-1336" |

| 改良ブロック体を有する砂質地盤の地震中液状化・地震後沈下挙動の3次元水~土連成解析 | 高稲敏浩,野田利弘,浅岡顕,竹内秀克 | "第43回地盤工学研究発表会(広島) pp.1583-1584" |

| 補強盛土と基礎地盤の連成挙動に関する水~土連成動的/静的解析 | 竹内秀克,野田利弘,中井健太郎,浅岡顕 | "第43回地盤工学研究発表会(広島) pp.1597-1598" |

| "性能設計に向けた合理的な締固め改良範囲に関する研究 -その1:建築構造物を対象とした場合-" | 安田進,原田健二,新川直利,有山裕亮,長谷川健太,荒木康志 | "第43回地盤工学研究発表会(広島) pp.1609-1610" |