Ground Improvement Business

Foundation of Ground Improvement

Pioneer of the Sand Compaction Pile Method

In 1956 Fudo Tetra was first in the world to develop the sand compaction pile method, which is now the most common method of ground improvement.

We have continued research and development since that time, and now as experts in geotechnical engineering

we have a wealth of design and implementation technologies and long experience in installation work.

All types of structures—buildings, roads, bridges and so on—are built on the ground. The condition of the ground is not fully apparent to the naked eye. To preclude damage from subsidence, landslips and similar threats to built structures, a thorough understanding of the nature of the ground is essential to prepare it for the type of structure to be built on it. In 1956 Fudo Tetra succeeded in developing the sand compaction pile method (traded as the Compozer method) as a world-wide first, and since then has used its expertise to develop many ground improvement technologies, contributing to ground preparation both in Japan and overseas.

Overseas activity of Fudo Tetra Corporation

Ground Improvement Technologies

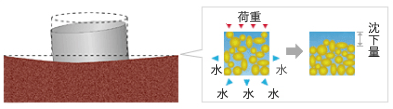

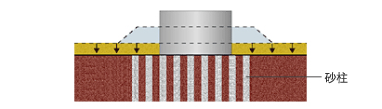

Problem:

- When ground is highly compressible, problems such as consolidation settlement or negative friction on piles occur. There are concerns that, after building is finished, subsidence in the ground could cause a structure to tilt or underground pipes to be damaged.

Answer:

- Settlement countermeasures (improving compressibility)

-

Example:

Advance completion of consolidation settlement through sand columns and advance earth filling equivalent to the load of the structure.

Suitable Methods

- Consolidation, drainage and compaction

- Consolidation acceleration

- Solidification

- Lightweight soil

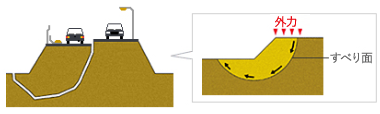

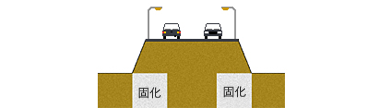

Problem:

- In weak ground, such issues as slipping failure of earth fill, loss of foundation bearing capacity, wall stability problems or inadequate lateral resistance of piles occur. Slippage damage occurs because the foundation ground lacks shear strength.

Main countermeasures:

- Stability increase (improvement for shear characteristics)

-

Example:

Shear strength of weak ground is boosted by mixing methods etc.

Suitable Methods

- Increasing bearing capacity

- Consolidation, drainage and compaction

- Solidification

- Stabilizing slippage

- Consolidation, drainage and compaction

- Solidification

- Increasing lateral resistance

- Consolidation, drainage and compaction

- Solidification

- Lightweight soil/fluidized soil

- Soil/slope retaining

- Solidification

- Water cutoff

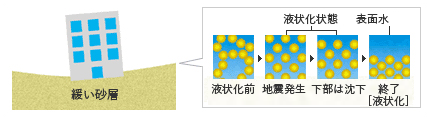

Problem:

-

When the friction force binding together sand particles in low density sandy ground breaks down due to seismic shaking, the ground becomes sand floating in water and this phenomenon is called liquefaction.

Liquefaction can cause the subsidence or tilting of structures.

Countermeasure:

- Liquefaction mitigation

-

Example:

By installing large-diameter well compacted high-density sand piles in loose sandy ground, the ground is stabilized, mitigating liquefaction.

Effect:

Effect of liquefaction countermeasures in ground damaged by seismic shaking:

* Great East Japan Earthquake, Tohoku, 2011

In the Great East Japan Earthquake of 2011, liquefaction occurred over a wide expanse of 42km2 of reclaimed land in the Tokyo Bay area.

However, it was confirmed that no damage was suffered at locations where Fudo Tetra had undertaken ground improvement work.

Built facilities

Outside area of improved ground

Area of ground improved by Fudo Tetra

- See details

-

Close

River embankments

Outside area of improved ground

Area of ground improved by Fudo Tetra

Highways

Outside area of improved ground

Area of ground improved by Fudo Tetra

● Great Hanshin Earthquake (1995)

In the Great Hanshin Earthquake of 1995, liquefaction occurred widely in areas of loose sandy soil along coastal zones and in reclaimed land such as Port Island and Rokko Island in Kobe, causing considerable structural damage. However, there were no reports of liquefaction in areas of improved ground where Fudo Tetra had implemented compaction methods, despite the very strong seismic shaking.

Kobe Port Island

Outside area of improved ground

Area of ground improved by Fudo Tetra

Outside area of improved ground

Area of ground improved by Fudo Tetra

Main Countermeasure Methods

- Compaction

- Solidification

- Drainage

- Others

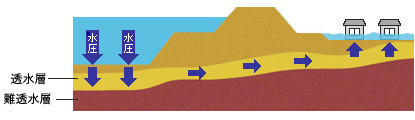

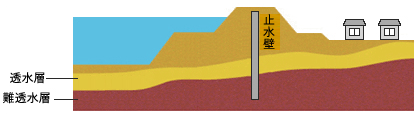

Problem:

- In locations adjacent to rivers where the groundwater level is high, raised water level outside the embankment causes water pressure to rise and flooding then occurs.

Countermeasure:

- Water Cutoff

-

Example:

Cutting off water to the permeable layer beneath an embankment prevents a rise in water level in the ground inside the embankment.

Methods:

- Water Cutoff

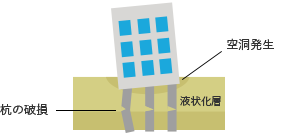

Problem 1

- Concerns are raised that voids may develop under foundations or uneven subsidence may occur in the surrounding ground due to piles damaged by liquefaction or post-liquefaction ground subsidence.

Countermeasure 1

- For both pile foundations and ground improvement

-

Example:

Ground improvement of the liquefaction layer prevents liquefaction occurring during an earthquake and also increases lateral resistance of the piles, reducing the cost of foundation piles.

Problem 2

- Concerns are raised that when lengthy supporting piles are needed the cost increases, and additionally that if liquefaction occurs piles may be damaged and consolidation settlement may lead to negative friction.

Countermeasure 2

- Spread foundations

-

Example:

Spread foundations through ground improvement are a measure to combat insufficient support, settlement and liquefaction. If subsidence is not a problem, improvement can be taken to middle layer, saving on costs.

Main Countermeasure Methods

- Compaction

- Solidification

- Lightweight soil/Fluidized soil

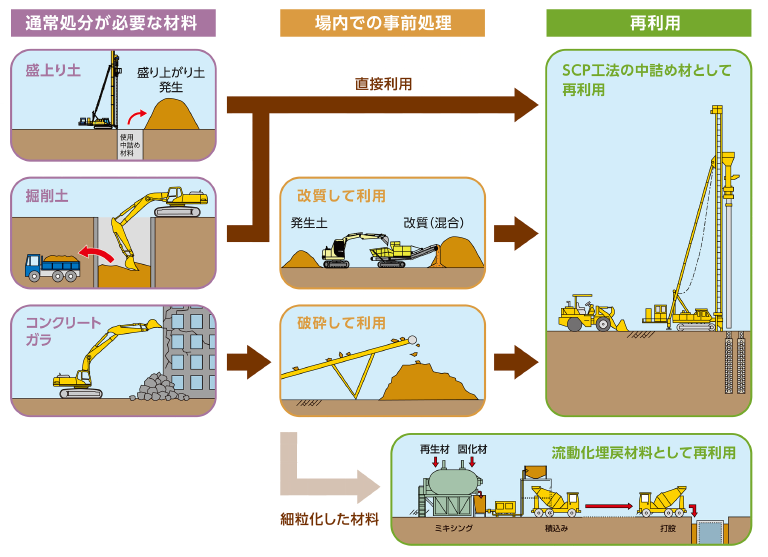

Total Re-soil System

-

Construction-generated soil from digging operations, concrete rubble from demolition work, or upheaved soil from sand pile installation is recycled locally for effective use as compaction material for ground improvement work with a Compozer, or as lightweight mixed soil.

Soil or rubble generated on site is usually transported off site for disposal, but this system avoids this transportation cost and its impact on the local environment. It also avoids the cost of purchasing and transporting sand or other compaction material plus the environmental impact of its extraction and transportation.

Outline of Total Re-Soil System

Eco-Gaia-Stone

- Earth Pile Foundations and Ground Improvement

-

A new filling material for use in the sand compaction pile method, made from steel industry slag. Grain size and expansion rate are controlled.

Coastal Development Institute of Technology validation #10001

NETIS registration KTK-140002-A〔Eco-Gaia-Stone Features〕

- Has the same compactability and ease of use as sand materials

- Possible to control consolidation quality by hydraulic regulation

- Environment-friendly

- Controls expansion stability

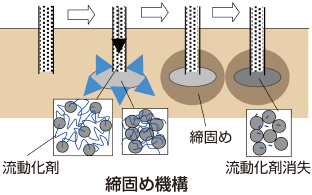

Fluidized Sand

- A material in which anion-type fluidizing agent L1, and cation-type plasticizing agent P1 that has the effect of aggregating the fluidizing agent, are mixed with sand. This material delivers fluidity due to L1’s ability to hold water, allowing passage through pipes and installation in the ground, the generation of an internal friction angle when compacted in the ground, and loss of fluidity after implementation. It has frequently been used as a liquefaction countermeasure in confined locations with the SAVE-SP method. It’s also a material that can possibly be used for filling voids after pile extraction etc.

Fudo Tetra’s Technologies

| Effect | Implementation conditions | NETIS registration data | NNTD registration data | Recognized technologies | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stopping | Support | Reducing load/filling | Protection | Offshore implementation possible | Low vibration, low noise | Low displacement implementation | Can handle re-used material | Can handle implementation over mud | Space and height restrictions | ||||||||||||

| Preventing subsidence | Mitigating liquefaction | Preventing slippage | Soil/slope retaining | Water cutoff | Digging stability | Increased bearing capacity strength | Increased lateral resistance of pile | Load reducing | Void filling | Soil decontamination | Containment | ||||||||||

| SAVE Compozer (Non-vibratory sand compaction pile method) |

● | ● | ● | ● | ● | ● | ▲ | ● | ● | ● | ● | ● | ● | ||||||||

| SAVE Compozer HA (Non-vibratory sand compaction pile method) |

● | ● | ● | ● | ● | ● | ▲ | ● | ● | ● | ● | ● | |||||||||

| SAVE marine method (Non-vibratory, low-noise type offshore sand compaction pile method) |

● | ● | ● | ▲ | ● | ● | ▲ | ● | ● | ● | |||||||||||

| Compozer (Sand compaction pile method) |

● | ● | ● | ▲ | ● | ● | ▲ | ● | ● | ||||||||||||

| Re-soil Compozer (Compozer utilizing construction-generated soil) |

● | ● | ● | ▲ | ● | ● | ▲ | ● | 〇 | ||||||||||||

| Effect | Implementation conditions | NETIS registration data | NNTD registration data | Recognized technologies | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stopping | Support | Reducing load/filling | Protection | Offshore implementation possible | Low vibration, low noise | Low displacement implementation | Can handle re-used material | Can handle implementation over mud | Space and height restrictions | ||||||||||||

| Preventing subsidence | Mitigating liquefaction | Preventing slippage | Soil/slope retaining | Water cutoff | Digging stability | Increased bearing capacity strength | Increased lateral resistance of pile | Load reducing | Void filling | Soil decontamination | Containment | ||||||||||

| Sand drain method | ● | ▲ | ▲ | ▲ | ▲ | ▲ | ● | ● | |||||||||||||

| CF drain method (Partially covered sand drain method) |

● | ▲ | ▲ | ▲ | ▲ | ▲ | ● | ||||||||||||||

| Resoil drain method (Drain method utilizing construction-generated soil) |

● | ▲ | ▲ | ▲ | ▲ | ▲ | ● | 〇 | |||||||||||||

| Pack-drain method (Bagged sand drain method) |

● | ▲ | ▲ | ▲ | ▲ | ▲ | ● | ||||||||||||||

| Plastic board drain method | ● | ▲ | ▲ | ▲ | ▲ | ● | ● | 〇 | |||||||||||||

| CS drain method (Plastic drain method management system) |

● | ▲ | ▲ | ▲ | ● | ● | 〇 | ||||||||||||||

| Vacuum consolidated drain method Consolidated drain method using capped drains | ● | ▲ | ▲ | ▲ | ● | ● | ● | ● | |||||||||||||

| Fiber drain method (Natural fiber drain method) |

● | ▲ | ▲ | ▲ | ● | ● | ● | 〇 | |||||||||||||

| PDF method (Floating type plastic board drain method) |

● | ▲ | ▲ | ▲ | ● | ● | ● | ||||||||||||||

| Effect | Implementation conditions | NETIS registration data | NNTD registration data | Recognized technologies | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stopping | Support | Reducing load/filling | Protection | Offshore implementation possible | Low vibration, low noise | Low displacement implementation | Can handle re-used material | Can handle implementation over mud | Space and height restrictions | ||||||||||||

| Preventing subsidence | Mitigating liquefaction | Preventing slippage | Soil/slope retaining | Water cutoff | Digging stability | Increased bearing capacity strength | Increased lateral resistance of pile | Load reducing | Void filling | Soil decontamination | Containment | ||||||||||

| SAVE-SP method (Sand infusion, non-vibratory compaction method) |

● | ▲ | ● | ● | ● | ● | ● | ● | |||||||||||||

| Vibro-rod method (Vibrating rod method) |

▲ | ● | ● | ● | |||||||||||||||||

| Mammoth vibro-tamper method (Surface layer compaction method) |

▲ | ● | ● | ||||||||||||||||||

| Compaction grouting Denver system (Static compaction method by grouting) |

● | ● | ● | ● | |||||||||||||||||

| Effect | Implementation conditions | NETIS registration data | NNTD registration data | Recognized technologies | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stopping | Support | Reducing load/filling | Protection | Offshore implementation possible | Low vibration, low noise | Low displacement implementation | Can handle re-used material | Can handle implementation over mud | Space and height restrictions | |||||||||||||

| Preventing subsidence | Mitigating liquefaction | Preventing slippage | Soil/slope retaining | Water cutoff | Digging stability | Increased bearing capacity strength | Increased lateral resistance of pile | Load reducing | Void filling | Soil decontamination | Containment | |||||||||||

| Mechanical mixing | CI-CMC method (Large-diameter, superior quality deep mixing method) |

● | ● | ● | ● | ● | ● | ● | ● | ▲ | ● | ● | ● | ● | ● | ● | ● | |||||

| CI-CMC-HA method (Large-diameter, low displacement deep mixing method for hard ground) |

● | ● | ● | ● | ● | ● | ● | ● | ▲ | ● | ● | ● | ● | ● | ● | |||||||

| CI-CMC-HG method (Large-diameter, low displacement deep mixing method for ultra hard ground) |

● | ● | ● | ● | ● | ● | ● | ● | ▲ | ● | ● | ● | ● | ● | ||||||||

| CMC method (Cement deep mixing (CDM) method) |

● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| CDM-LODIC method (Displacement reduction type deep mixing method) |

● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| TOFT method (Grid-type solidification method) |

● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ▲ | ● | ● | |||||||||

| DJM method (Powder discharge mixing method) |

● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| ALiCC method (Low improvement ratio cement column method) |

● | ● | ● | ▲ | ● | |||||||||||||||||

| Power blender method (Shallow and intermediate layer mixing method) |

▲ | ▲ | ● | ▲ | ● | ▲ | ▲ | ▲ | ● | ● | ● | ● | ● | |||||||||

| With Compaction | HCP method (Hardening compaction method) |

● | ● | ● | ● | ● | ● | |||||||||||||||

| GCCP method (Gravel cement compaction pile method) |

● | ● | ● | ▲ | ● | ● | ||||||||||||||||

| Composite Mixing | JACSMAN (Cross jetting type composite mixing method) |

● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| PJ method (Cross jetting type composite mixing method using compact equipment) |

● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| Jet Mixing | FTJ method (Twin flow cement slurry jet mixing method) |

● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| FTJ-FAN method (Swing-type multi-flow cement slurry jet mixing method) |

● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| Super jet method (High pressure jet mixing method (large diameter)) |

● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| Surface Layer Mixing | Consolider method (Surface layer solidification method) |

▲ | ▲ | ● | ▲ | ● | ▲ | ● | ▲ | ● | ● | |||||||||||

| V-mixing method (Surface layer solidification method (horizontal propelling trencher)) |

▲ | ▲ | ● | ▲ | ● | ▲ | ● | ▲ | ● | ● | ||||||||||||

| Premixing | Barge consolider method (Premixing method) |

▲ | ● | ▲ | ● | ● | ● | |||||||||||||||

| Grouting Solidification | Permeating solidification method | ▲ | ● | ▲ | ● | ● | ● | 〇 | ||||||||||||||

| Continuous Diaphragm Wall | TRD method (Continuous soil cement diaphragm wall method) |

▲ | ▲ | ▲ | ● | ● | ● | ● | ● | ● | 〇 | |||||||||||

| Effect | Implementation conditions | NETIS registration data | NNTD registration data | Recognized technologies | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stopping | Support | Reducing load/filling | Protection | Offshore implementation possible | Low vibration, low noise | Low displacement implementation | Can handle re-used material | Can handle implementation over mud | Space and height restrictions | ||||||||||||

| Preventing subsidence | Mitigating liquefaction | Preventing slippage | Soil/slope retaining | Water cutoff | Digging stability | Increased bearing capacity strength | Increased lateral resistance of pile | Load reducing | Void filling | Soil decontamination | Containment | ||||||||||

| Sheet wall method (Special lightweight steel sheet pile water cutoff method) |

● | ● | ● | ● | ● | ||||||||||||||||

| Geolock method (Vertical sheet pile method) |

● | ● | ● | ● | ● | ||||||||||||||||

| Trinner method (Triple layer water cutoff wall method) |

● | ● | ● | ● | ● | ● | |||||||||||||||

| Effect | Implementation conditions | NETIS registration data | NNTD registration data | Recognized technologies | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stopping | Support | Reducing load/filling | Protection | Offshore implementation possible | Low vibration, low noise | Low displacement implementation | Can handle re-used material | Can handle implementation over mud | Space and height restrictions | ||||||||||||

| Preventing subsidence | Mitigating liquefaction | Preventing slippage | Soil/slope retaining | Water cutoff | Digging stability | Increased bearing capacity strength | Increased lateral resistance of pile | Load reducing | Void filling | Soil decontamination | Containment | ||||||||||

| LSS method (Fluidized soil placement method) |

● | ▲ | ● | ▲ | ▲ | ● | ● | ▲ | ● | ● | |||||||||||

| Georaft method (High-strength high-quality fluidized soil placement method) |

● | ▲ | ● | ● | ● | ● | ● | ▲ | ● | ● | |||||||||||

| High-grade soil (Mixed strengthened soil method) |

● | ▲ | ● | ● | ● | ● | ▲ | ● | ● | ||||||||||||

| SGM lightweight soil method (Air bubble incorporated soil method) |

● | ▲ | ● | ● | ● | ● | ▲ | ● | ● | ||||||||||||

| Effect | Implementation conditions | NETIS registration data | NNTD registration data | Recognized technologies | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stopping | Support | Reducing load/filling | Protection | Offshore implementation possible | Low vibration, low noise | Low displacement implementation | Can handle re-used material | Can handle implementation over mud | Space and height restrictions | ||||||||||||

| Preventing subsidence | Mitigating liquefaction | Preventing slippage | Soil/slope retaining | Water cutoff | Digging stability | Increased bearing capacity strength | Increased lateral resistance of pile | Load reducing | Void filling | Soil decontamination | Containment | ||||||||||

| Gravel drain method (Gravel drain method) |

● | ● | ● | ● | |||||||||||||||||

| NUP gravel drain method (Gravel piling with compaction method) |

● | ● | ● | ||||||||||||||||||

| Effect | Implementation conditions | NETIS registration data | NNTD registration data | Recognized technologies | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stopping | Support | Reducing load/filling | Protection | Offshore implementation possible | Low vibration, low noise | Low displacement implementation | Can handle re-used material | Can handle implementation over mud | Space and height restrictions | ||||||||||||

| Preventing subsidence | Mitigating liquefaction | Preventing slippage | Soil/slope retaining | Water cutoff | Digging stability | Increased bearing capacity strength | Increased lateral resistance of pile | Load reducing | Void filling | Soil decontamination | Containment | ||||||||||

| Air-des method (Air-incorporated desaturation method) |

● | ● | ● | ● | |||||||||||||||||

ICT Ground Improvement

FudoTetra Ground Improvement is Combined with ICT for Further Innovation

Japan’s Ministry of Land, Infrastructure, Transport and Tourism aims to boost overall productivity in construction through the application of ICT on all fronts, and is promoting i-Construction to add more attractive features to construction sites. Accordingly, Fudo Tetra is developing ICT ground improvement technology that combines ground improvement with ICT for revolutionary change to productivity on construction sites by promoting upgraded productivity, safety and quality, visibility and a tradition of technology.

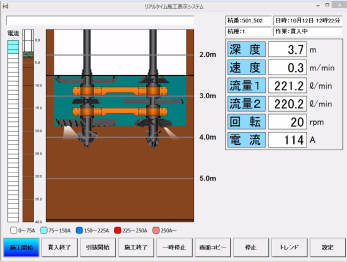

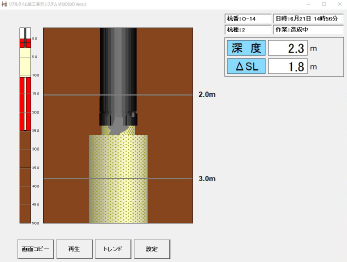

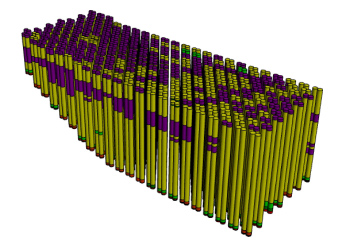

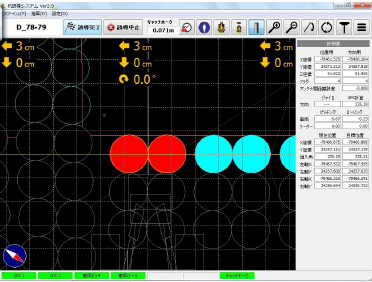

Visios-3D®A real-time implementation management system + 3-dimensional modeling system

An implementation management system that allows the operational status of the installation rig to be monitored from a remote location. Multiple staff can share the data simultaneously on tablet screens. Implementation records can be converted into 3D models conforming with the Ministry’s CIM.

Visios® is a registered trademark of Fudo Tetra and the series name for technologies making site operations visible.

Tablet screen (CI-CMC)

Tablet screen (SAVE-SP)

Remote monitoring

3D model of implementation records

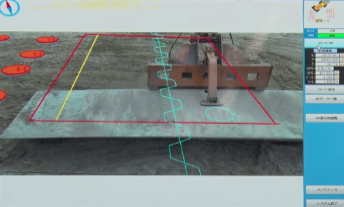

Visios-ARMultipurpose implementation support device using augmented reality

An augmented reality (AR) system fitted to backhoes and excavators for supplementary support. Images captured by cameras are overlaid with data such as positioning for scaffolding or objects buried in the ground and displayed in real time. This supplementary support is possible even for sites where markers are no longer needed on the ground due to use of GNSS.

AR hearing status

Tablet screen (AR)

Tablet screen (2D)

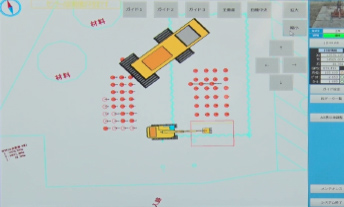

GNSS Ground Improvement Rig Guidance SystemNETIS : CG-120020-VE

A system that displays positions for pile driving and rig location on the monitor in the operator’s cab, so that guidance on positioning is no longer required on the ground. This saves on manpower and also has safety benefits, as personnel are not required to approach the rig.

This system has been jointly developed by Fudo Tetra and Nishio Rent All Co., Ltd.

Guidance screen

Fitted with GNSS antenna

Working Vessel Location, Shipping Navigation Data System

A system to cover the whole of Japan that records and displays the current position and navigation of working vessels offshore. The position of shipping can be checked at any time through the internet from a laptop or smartphone.

This system is a service provided by All Japan Fishing Port Construction Association.

SCP barge working offshore

Screen of working vessel position data

Technologies & Solutions

READ MOREAchievements

READ MORE