Compaction with a Small Sized Rig and Pumped Conveyance of Fluidized Sand

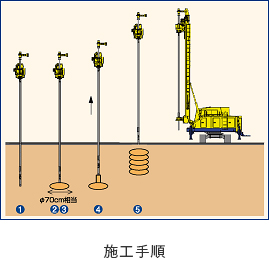

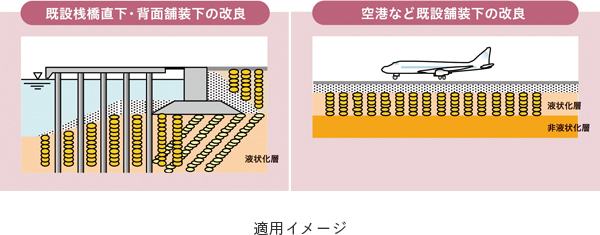

The SAVE-SP method achieves compaction with a very small rig through pumped conveyance of fluidized sand. Sand mixed with fluidizing agent is pumped into the ground through a rod installed to the required depth and the surrounding ground is compacted. The fluid state of the sand is terminated by draining when discharged, and through the use of an added slow-acting plasticity agent. This method makes ground compaction possible for a range of site conditions where improvement has been difficult up to now, such as at confined sites or directly beneath existing structures.

| New civil engineering technology | June 2018 NNTD Agricultural and Rural Development Technical Database, Registration #1252 May 2016 2016 Japan Construction Machine Implementation Grand Prize, Distinction Award 2016年4月 平成28年度「推奨技術」(新技術活用システム検討会議<国土交通省>選定 October 2014 Japan Institute of Country-ology and Engineering (JICE) Construction Technology Screening Certificate #37 July 2012 14th Ground Technology Development Award June 2012 Japanese Geotechnical Society, Technical Development Award |

|---|

Features

- Can be implemented on confined sites

The compact rig (approx. 5m high x 2.5m wide) allows implementation in tight spaces or on quays. It is easily transported and can be used for emergency standby at airports etc. - Can be applied directly beneath existing structures

Only a rod about 10cm in diameter is driven into the ground to be improved. It can also be utilized diagonally or for layers with hard obstacles.

It can be implemented through a small aperture of about 15cm beneath existing paved surfaces, quayside structures or objects in the ground, and subsequent restoration is straightforward. - Non-vibratory, low noise

The vibratory equipment of the SCP method is not used, making quiet ground compaction possible. - Highly economical

This method is extremely economical compared with existing liquefaction countermeasures for use in confined spaces or directly beneath existing structures.

>> Implementation capacity can be doubled; costs cut 20-30% - Low environmental impact

Use of compact equipment and natural material (sand) is environment-friendly.