- Project Stories

- River Works

Restoring Floodgates with Historical and Cultural Significance

Restoration of damaged Nobiru floodgates of the Naruse River, Miyagi Prefecture

Project Responsibility

Technology Department, Civil Engineering Business Division

Joined 1993

Akira Yamashita

“It was often difficult to procure materials due to the heavy demand after the Great East Japan Earthquake of 2011. In particular, it was difficult to obtain fresh concrete: it needed to be reserved well in advance of the day it was needed, and organizing the schedule was hard. There were also jobs such as bricklaying and moving gates that are not normally encountered in civil engineering, so it was a valuable experience.”

Installing the New Floodgates

Behind the Existing Floodgates

The Nobiru floodgates that link the Tomei Canal and the Naruse River were installed in 2003 to prevent water flowing from the river back into the canal at times of high tide or flood. In consideration of the scenery, they featured a low height design with miter gates. This job involved building up the embankments and constructing a new gateway with the old gates still in place in front.

- SCENE

- 01

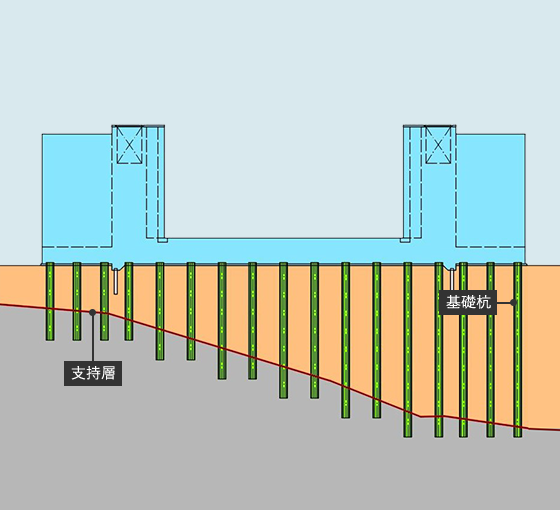

Checking Bearing Layer and Installing Piles with Precision

The design for the Nobiru floodgates included installing foundation piles (steel pipe piles) in the ground to support the gates—specifically, driving the tip of the piles into the bearing layer. The bearing layer of hard rock sloped towards the sea, so the usual method of driving the foundation piles into the ground risked the tips of the piles slipping sideways. Therefore the steel pipe soil cement method was employed to bore into the ground down to the bearing layer and install the piles. Rechecking the complex slope with boring surveys avoided installing piles of insufficient length.

- SCENE

- 02

Durability Improved by Preventing Rusting of Re-bars

As the floodgates are close to the shore, the steel reinforcement in the concrete was thought vulnerable to rust. Salt causes rusting and penetrates the concrete through fine cracks, so fine cracks were minimized through temperature control and the steel frame was coated with anti-rusting agent.

- SCENE

- 03

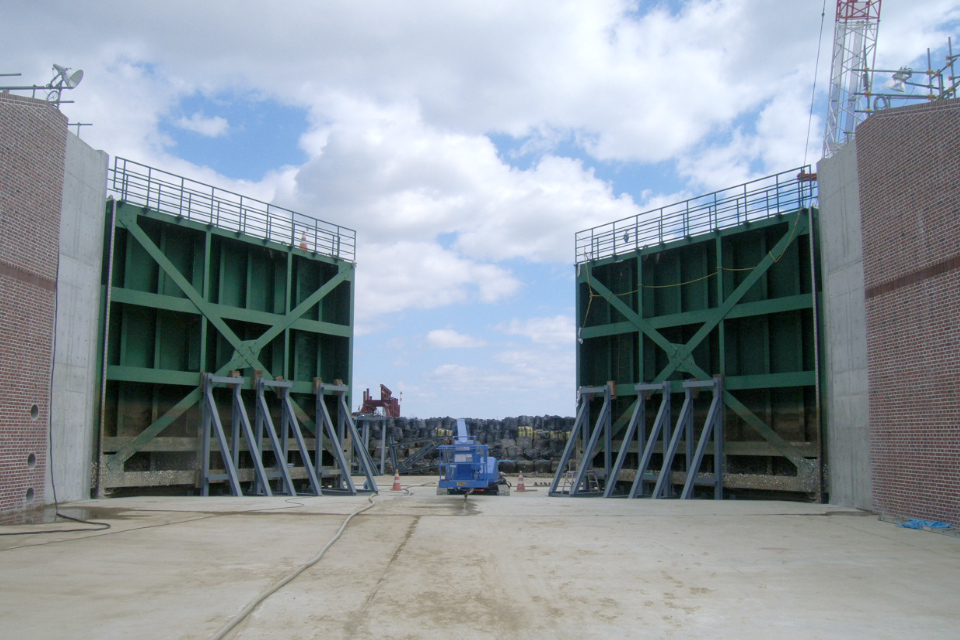

Faithful Reproduction of Materials and Construction Method

Around the floodgates is a brick-built bridging base and lock listed as a nationally important cultural property. Both were constructed in the late 19th century for Nobiru Port. As the existing part (from 2003) had been finished in brick for a harmonious appearance, brick was also used to finish the newly installed gateway section. To ensure the two sections matched, the company responsible for the earlier brickwork was commissioned to provide bricks fired at a higher temperature than usual to achieve the right look. The same English Bond Masonry Pattern as before was used for the brickwork, and experienced bricklayers undertook the work, brick by brick.

- SCENE

- 04

60ton Gates Moved without even a 1mm Gap

The former gates were finally moved to the new position and re-used. Each gate weighed 60ton and was raised with a 550ton crane. Repeated opening and closing plus the effect of the tsunami had greatly increased resistance where the gates had been hung, making it difficult to detach them. Three large hydraulic jacks were positioned at the base of each gate and the work progressed by tiny adjustments. There were concerns about the effect of the wind at the mouth of the Naruse river, so a top wind speed of 6m/sec was imposed, above which the work could not go ahead. Fortunately the weather was fine and although it took time to detach the gates, their transfer to their new position went smoothly.

GALLERY

| Client: | Ministry of Land, Infrastructure, Transport and Tourism; Tohoku Regional Development Bureau |

|---|---|

| Completed: | 2017 |

| Location: | Higashi Matsushima City, Miyagi Prefecture |

| Work Outline: |

Building gateway; moving gates; foundation work: 131 steel pipe soil cement piles; breakwater base work (foot protection blocks); 1,413 sand compaction piles installed (to counter liquefaction under breakwater), revetment work (river dike, slope pavement, crown cladding); road upgrading; removal of former gateway |

Other Project Stories

Technologies & Solutions

READ MOREAchievements

READ MORE