- Project Stories

- Harbor Works

Restoring Breakwater and Protecting Commercial Distribution Base

Restoration of damaged breakwater at Soma harbor, Miyagi Prefecture

Project Responsibility

Construction Department, Civil Engineering Business Division

Joined 2016

Yusuke Kinjo

“Meeting in the office before daybreak we collected all the weather and sea-related information, and with first light we checked on the waves to decide whether we could work that day. Many times we had to withdraw without working due to swell that was not visible to the eye or sudden fog, but we completed the work on schedule without problem. It was my first offshore job, and to me it seemed that everything had to be decided first thing in the morning.”

Implementing the Final Stage of Breakwater Restoration

The breakwater outside Soma port was severely damaged by the tsunami that accompanied the Great East Japan Earthquake. Restoration work began in earnest in March 2012 and was completed in March 2018. This job constituted the final stage of the restoration work and consisted of adding height to the concrete of the offshore breakwater and manufacturing and positioning wave-dissipating blocks. ICT was utilized for the efficient positioning of new blocks together with the blocks displaced by the tsunami.

- SCENE

- 01

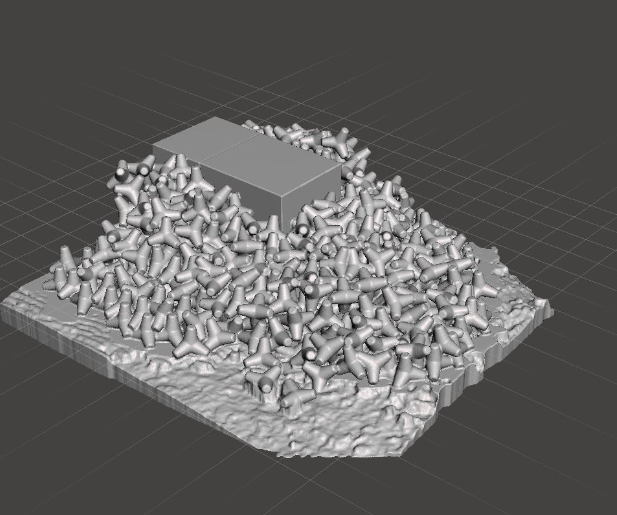

3D Survey for Full Picture

To determine the precise number of blocks needed for the restoration, 3D measuring utilizing ICT was employed. Drones and 3D laser scanners were used to survey above the water surface, while narrow multi-beam sonar equipment was used underwater. Combining the 3D data obtained from these sources gave a 3D view of the overall form of the wave-dissipating work.

- SCENE

- 02

Simulation using 3D Models

We generated a 1 : 58 scale model of the current state of the breakwater using a 3D printer. We used this for a placement simulation with model blocks to determine best practice in terms of positioning blocks and sequencing the work.

- SCENE

- 03

Blocks Positioned Accurately using AR (Augmented Reality)

To position the wave-dissipating blocks we made use of a block positioning imaging system developed by Fudo Tetra. This system displays markers in real time that indicate positions on actual images taken by a camera, cutting out the need for guidance from divers or staking work, and installation was completed safely and efficiently.

- SCENE

- 04

Combatting Rolling Waves

Soma port is one of the top ten ports in Japan in terms of its exposed marine conditions, and work could be undertaken for only about half of each month. The site faced the open sea, and waves were deflected back by the breakwater so there was constant swell. August, for example, allowed us only six days of work. We utilized resources to the full, bringing in 4 large crane barges (250~600ton lifting capacity) including our own vessel 2001 Tetra, and the job was completed without problem.

GALLERY

| Client: | Ministry of Land, Infrastructure, Transport and Tourism; Tohoku Regional Development Bureau | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Completed: | 2018 | ||||||||||||

| Outline of works: | Soma City, Fukushima Prefecture | ||||||||||||

| Work Outline: | Restoration to Soma Main Port offshore breakwater damaged by the Great East Japan Earthquake and Tsunami

Soma Port Main Port breakwater (offshore)

Soma Port Main Port breakwater (offshore)

|

Other Project Stories

Technologies & Solutions

READ MOREAchievements

READ MORE