- Project Stories

- Bridge

Constructing a major new highway artery for Japan

Supports for the Shimokasuya elevated section of the Shin Tomei Expressway

Project Responsibility

Construction Department, Civil Engineering Business Division

Joined in 2006

Mizuki Yamaguchi

“This job needed to stay on schedule, with each completed section handed over in turn, and so managing it was very tough. It was my first time being in charge on site for such a large project, but I had back-up from other sites and we got the job done.”

32 Foundations for Bridge Piers for the Shin Tomei Expressway

The Shin Tomei Expressway is a national project under the lead of the Central Nippon Expressway Co., Ltd. It has three objectives: to relieve congestion on the existing Tomei Expressway and provide upgraded services, to provide an alternative to the Tomei Expressway in the event of a natural disaster or major accident, and to better link up the three major metropolitan areas on its route. We constructed a total of 32 new pier foundations for Utagawa Bridge (1), Shimokasuya Daiichi Elevated Section (23) and Shimokasuya Overpass (8).

- SCENE

- 01

Securing Stable Construction Ground

The ground surface on site was an extremely soft 10m layer of organic soil. Firm ground that could support large-size equipment was essential for safe and precise construction work, and so ground improvement not included in the initial plan was recommended. For this we fell back on company expertise, and chose an economical method that would provide reliable quality, with minimal impact on the surrounding environment. With overall coordination from the planning phase to implementation, we were able to complete the work on time.

- SCENE

- 02

Care Taken Close to Steel Towers and Rail Tracks

The construction site included an area close to steel utility towers for high voltage cables and the Odakyu Odawara railway line (15m away at the closest point), and so it was important to prevent the work causing displacement around the steel towers or railway line. Prior investigations using FEM analysis were undertaken and information provided to the managements of the utility and the railway. During the implementation, constant monitoring avoided any adverse effect on the utility towers or railway.

- SCENE

- 03

Ensuring Quality of Foundation Piles by Strengthened Implementation Management

For the installation of steel pipe piles to underpin the bridge supports, from the surface down about 30m to the bearing layer, the main issues were the accurate positioning the piles and the depth to which they were driven. To ensure accuracy, GNSS was used in addition to the usual measuring method to double check pile positioning. To determine the depth of the pile tips and check they had reached the bearing layer, a system was set up whereby both client and contractor shared a range of measurements obtained during pile driving, to improve the reliability of the implementation management. By making these modifications, 378 piles were all accurately installed.

- SCENE

- 04

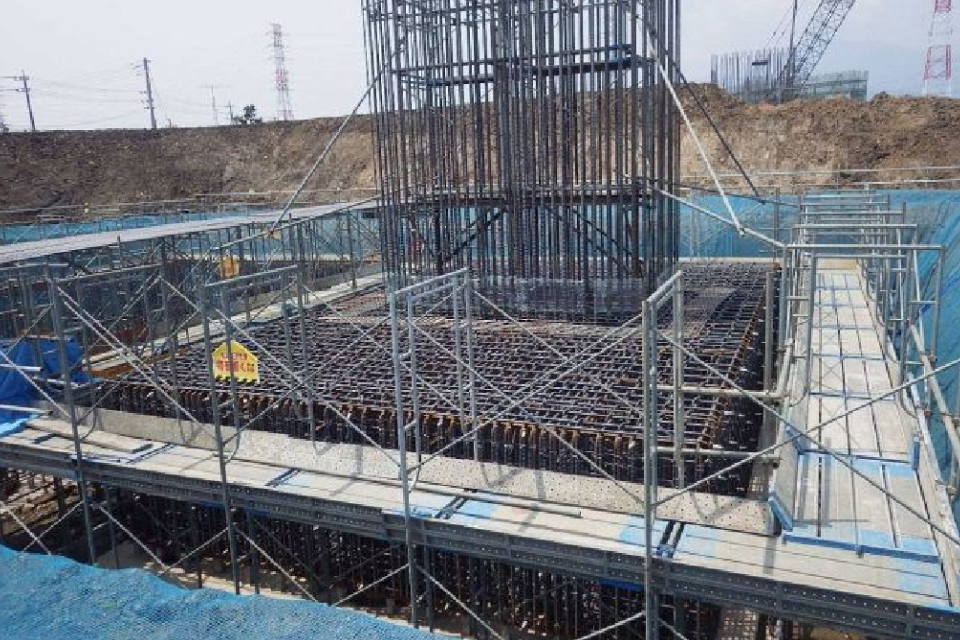

Using High-strength, High-durability Framework for Efficiency and Quality

Constructing the concrete structures takes the most time, and steel framework was used instead of the usual timber. Steel is much more rigid than timber, and so larger unit sizes could be used, boosting efficiency. In addition, highly durable stainless steel plate was used to cover the framework. Stainless steel faceplate is resistant to wear and rust. It guarantees the quality of the concrete surface, while allowing fast switching of the framework. The workmanship of the concrete piers was highly acclaimed by the client.

GALLERY

Other Project Stories

Technologies & Solutions

READ MOREAchievements

READ MORE