- Project Stories

- Mountain Tunnel

Constructing a Tunnel through the Mountain to Improve Traffic Flow

Kuchitagi No 1 Tunnel, Taki Asayama Highway, Izumo, Shimane Prefecture

Project Responsibility

Construction Department, Civil Engineering Business Division

Joined 1992

Takehiro Yamanaka

“There were new technologies that the company was using for the first time and at times I didn’t understand or it didn’t go well, but with the cooperation of others and the information provided the job went well with no problems and it was good experience for me.”

Tunnel Construction on the Taki-Asayama section of the San’in Expressway

Route 9 linking Izumo City with Ota City in Shimane Prefecture is a dangerous stretch of highway with sharp bends that have caused many accidents. It can also be closed from damage caused by heavy rain, so is prone to frequent problems. The Taki Asayama Highway is a 9km stretch of highway exclusively for motor traffic that was planned to resolve these issues. This project was to build a 354m tunnel using the New Austrian Tunneling method (NATM).

- SCENE

- 01

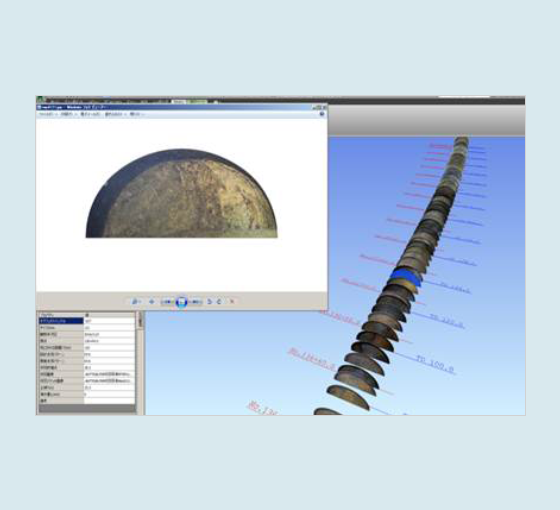

Efficient Project Management with the Use of CIM

Construction Information Modeling/Management, or CIM, was utilized for more efficient management and improved precision of the tunnel works.

Through links to CIM-created 3D models of measurement data from tunnel building and quality control records, it was planned to simplify data searches and make implementation management more efficient. Data from the construction work was accessible via the internet, which made data sharing with off-site engineers and other staff very smooth.

- SCENE

- 02

Eliminating Unevenness from Surface of Cladding Concrete

To prevent water leaking into mountain tunnels, waterproof sheeting about 1mm thick is attached to the concrete sprayed onto the dug surface of the tunnel, but this sheeting can be damaged by uneven rocky surfaces or projecting rock bolts. Kuchitagi No 1 tunnel passes through ground where permeating rain water reaches the tunnel, raising concerns that water would leak into the tunnel after completion, and so the space between the sprayed concrete and the waterproof sheeting was filled using the FILM (Flat Insulated Tunnel Lining) method to prevent damage to the sheeting. As a result, the waterproof sheeting did not come into contact with any uneven surface or projections, avoiding damage and upgrading waterproofing.

- SCENE

- 03

Better Quality of Cladding Concrete through Use of EPS Panel Curing Method

The cladding concrete that users notice as they pass through a tunnel must be prevented from breaking off through careful and proper application. Carrying out the cladding work in low winter temperatures raises concerns that cracks may occur while the concrete is hardening and durability may be compromised.

The EPS panel curing method developed by Fudo Tetra (NETIS : CB-090003-VE) was therefore used, and about four weeks of long-term curing took place immediately after the formwork was removed. The EPS panel curing method prevents cracks as the concrete dries out and maintains an appropriate temperature for hardening, so high quality cladding concrete was obtained.

- SCENE

- 04

Care Taken over Endangered Bird Species

During the building of the Taki Asayama Highway, nesting sites of an endangered bird species, the grey-faced buzzard, were identified in the area, and after an environmental assessment it was decided to lower the impact of the construction work. Low-noise equipment was used and work methods were modified to minimize noise and vibration. During the breeding season the use of cranes was disallowed in the areas of greatest concern.

GALLERY

Other Project Stories

Technologies & Solutions

READ MOREAchievements

READ MORE